Rubber & Plastic Mold Cleaning

Dry Ice Blasting Applications

Quickly, safely and efficiently clean your molds while improving OEE operational efficiencies

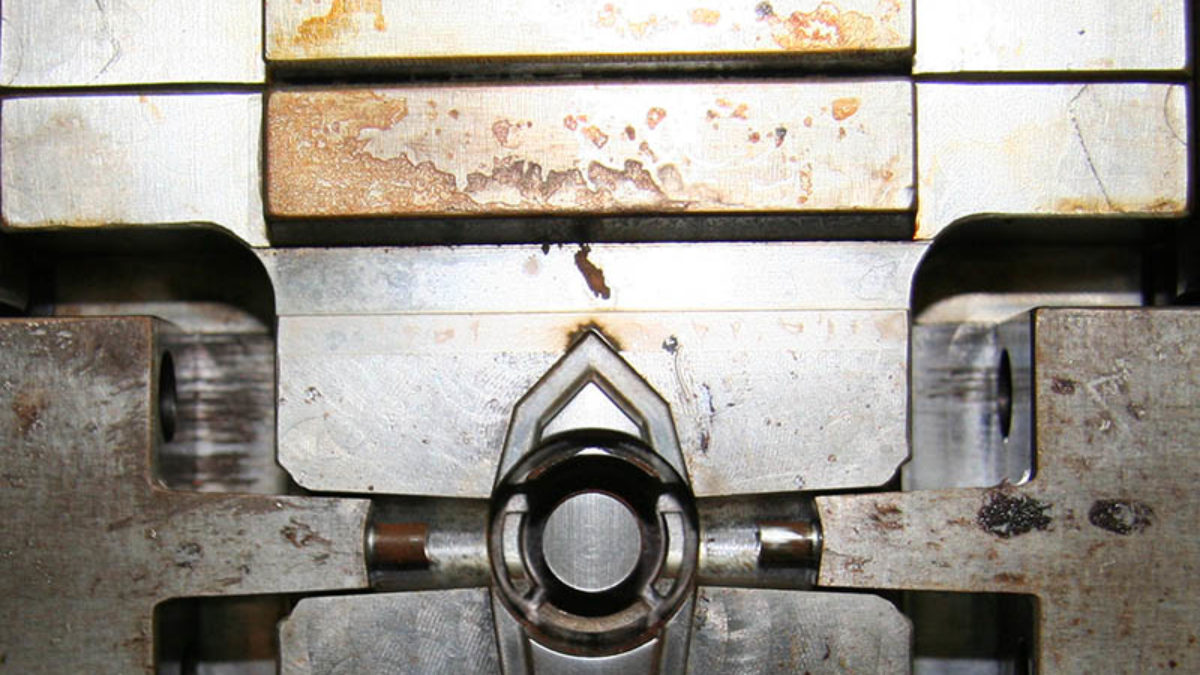

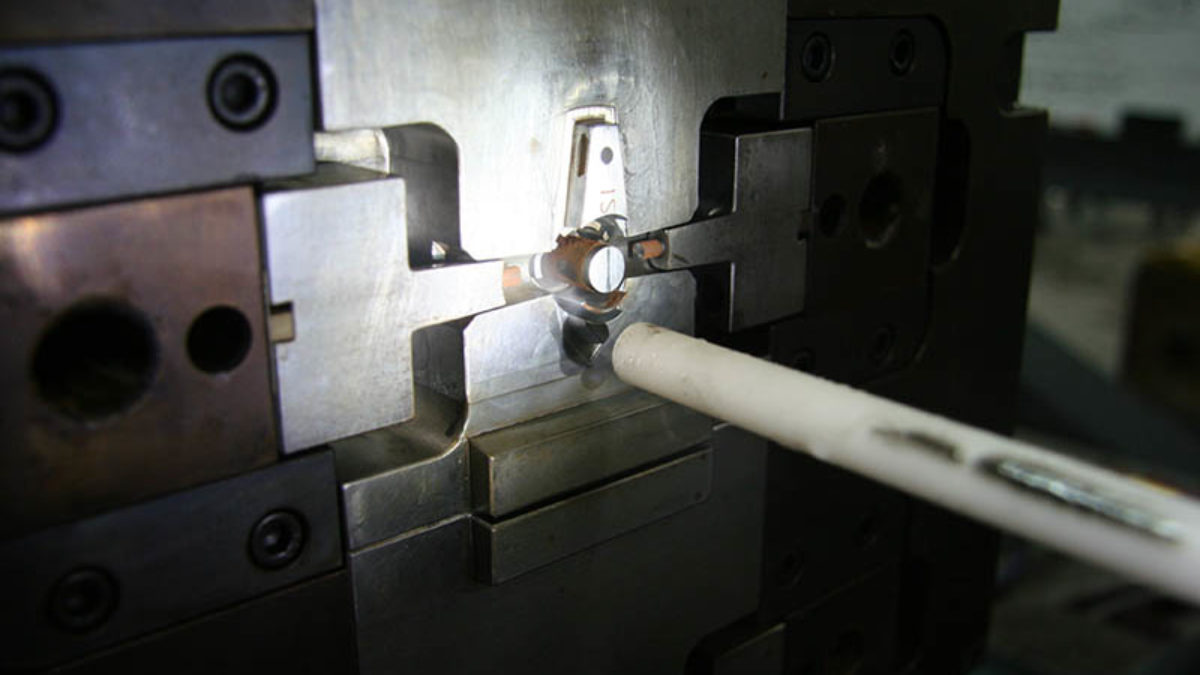

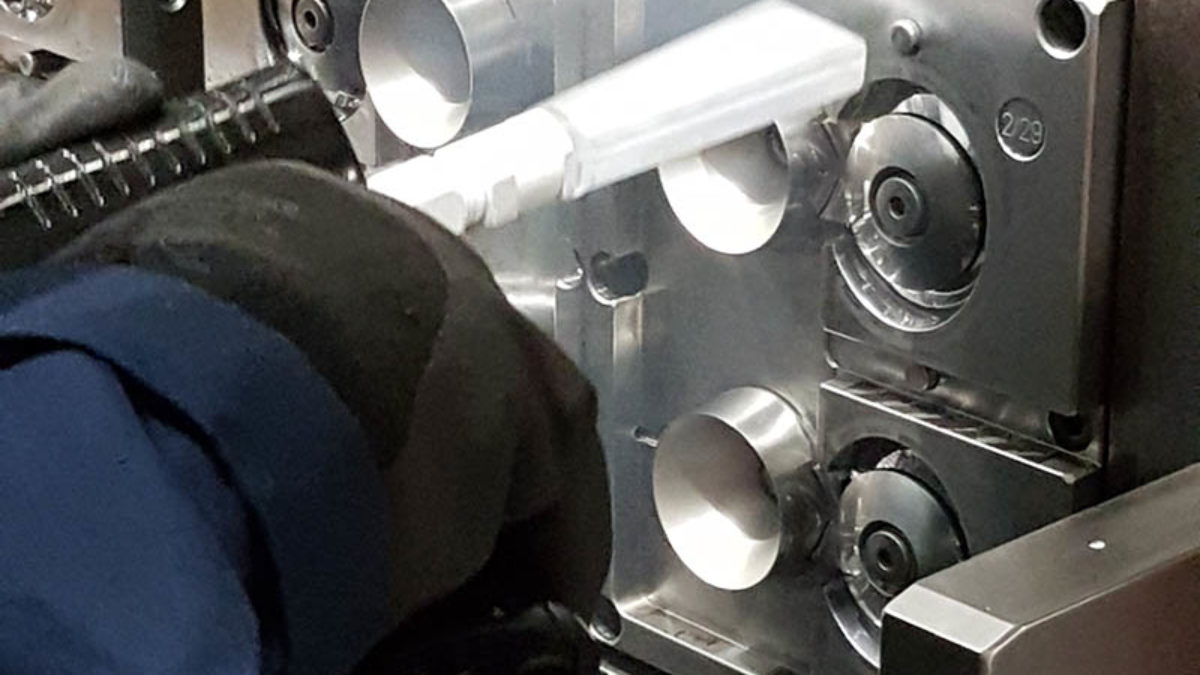

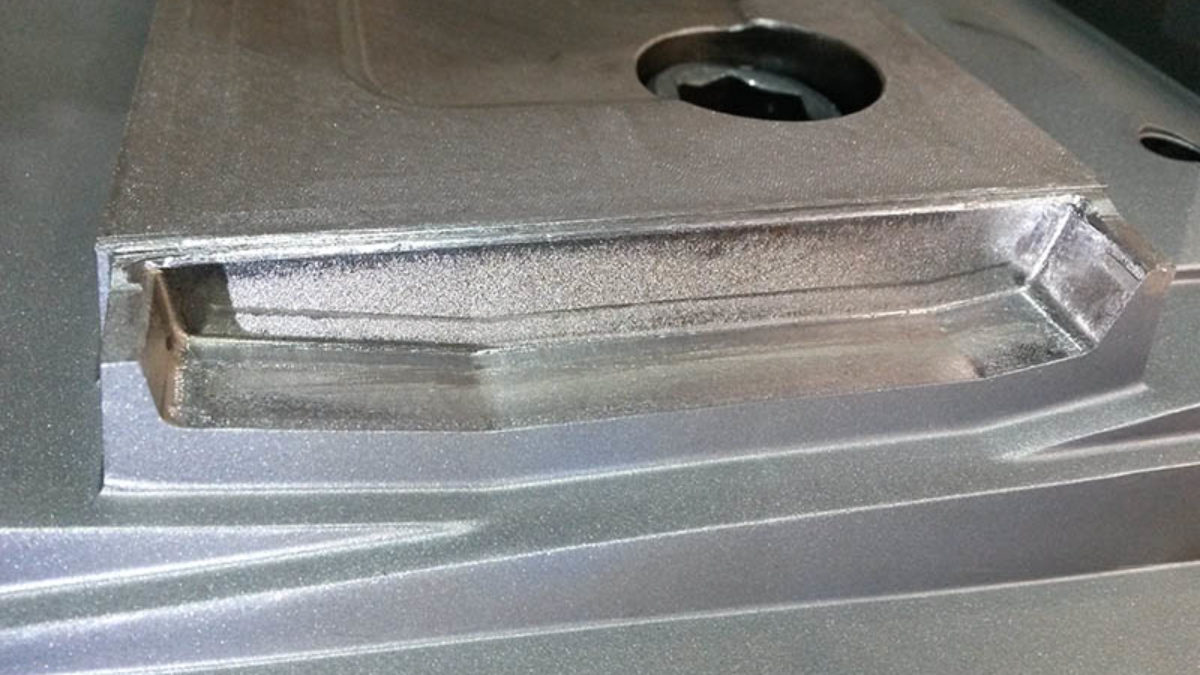

Dry ice blasting is non-abrasive, does not produce secondary waste and allows you to clean your molds in the press, at operating temperatures. The use of this equipment leads to improved productivity, higher quality parts and reduced costs.

The process can clean any type of mold and a variety of mold finishes up to and including A1 surfaces and textured surfaces. Learn more about industrial mold dry ice cleaning below.

Specific Use Cases

Dry ice blasting safely and effectively cleans all types of molds

- Injection molds

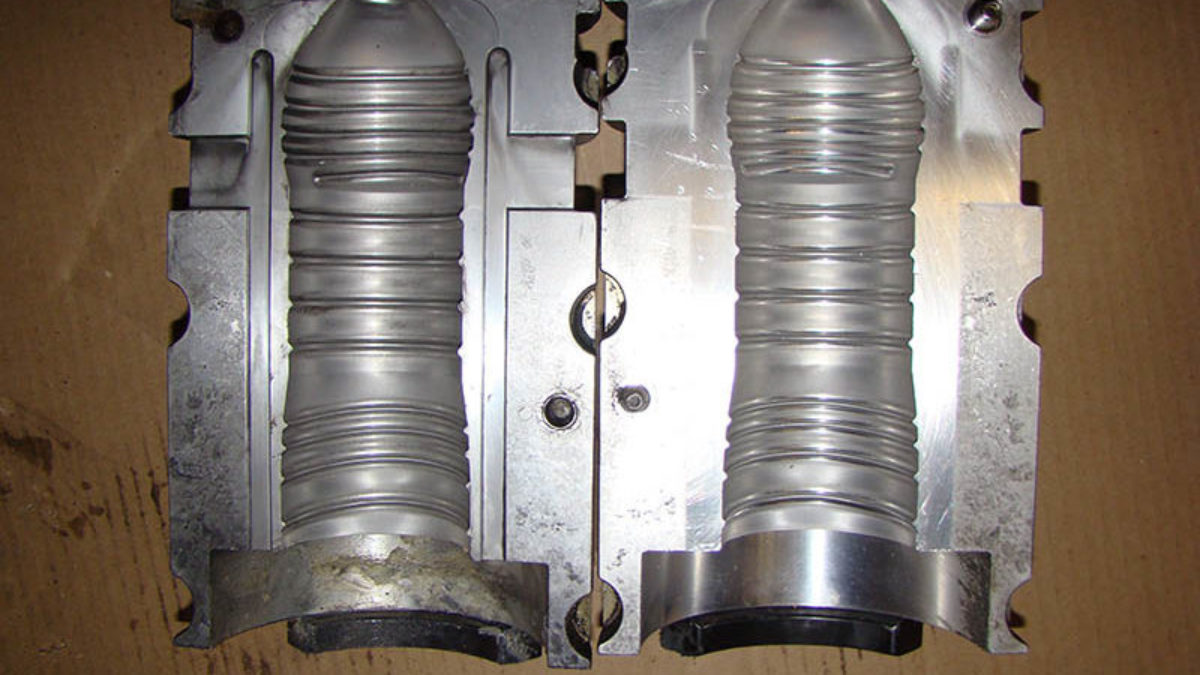

- Blow molds

- PET preform molds

- LSR and LIM molds

- Thermoform molds

- Urethane molds

- Technical molds

- Metal injection molds (MIM)

- Compression molds

- Fiberglass molds

- HDPE molds

- Medical device molds

- Extrusion dies

- Automotive molds

Related Industries

Benefits of Dry Ice Blasting

Cut costs, increase production efficiency and improve product quality

Dry ice blasting not only cleans your molds more effectively, but also leads to an increase in OEE operational efficiencies.

- Non-abrasive

Will not damage parting lines, sealing surfaces or surface finishes - No secondary wasteNo secondary cleaning process from solvent residue

- Clean molds online at operating temperatures

- Reduce downtime Clean faster with no disassembly required

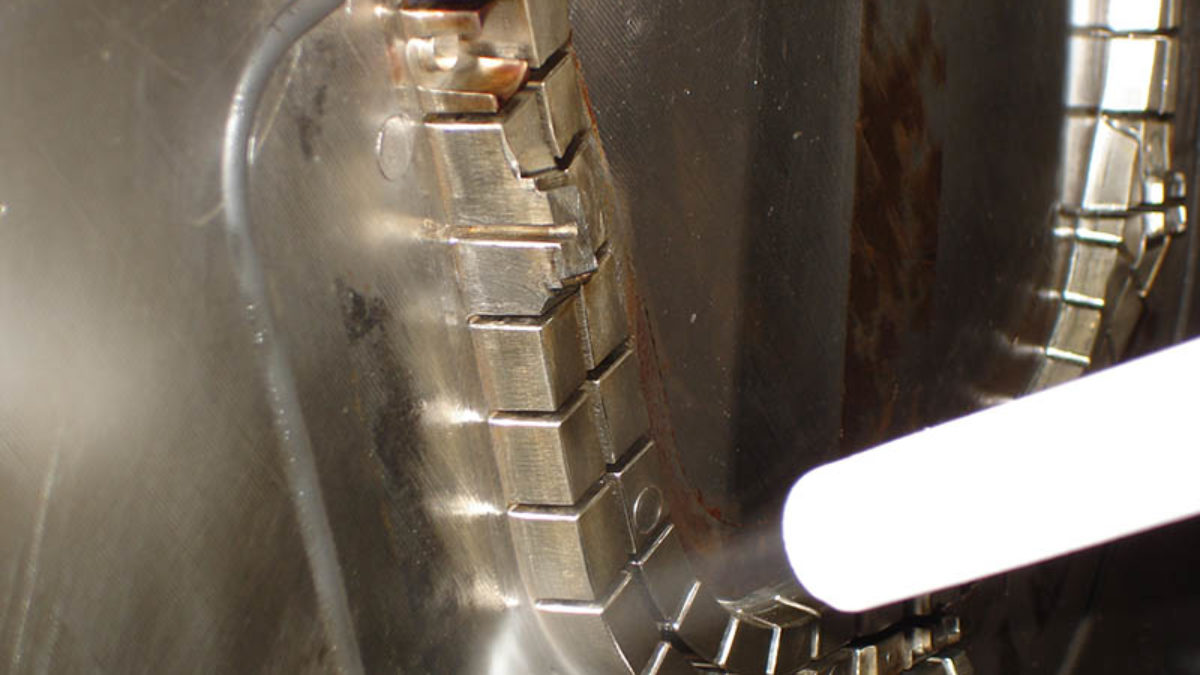

- Easily clean complex molds Access and clean complex mold geometries, such as cavities and vents

- Meet stringent productivity demands

Meet demands (6-Sigma, Kaizen, 5S, TPM) and improve OEE scores - Decrease CostsDecrease mold cleaning costs by as much as $50,000

- Reduce cleaning times Reduce cleaning times by as much as 75%

- Improve product quality and decrease scrap rates

- Extend asset life of the mold

- Environmentally sustainable

- Eliminate manual cleaning and harmful chemicals Safer for employees and the environment

Case Studies

Dry ice blasting is solving our customer’s pain points in their mold cleaning process

-

Plastics & Composites

Plastics & Composites -

Plastics & Composites

Plastics & CompositesPlastics processor reduces cleaning time from 4 hours to less than 10 minutes

Learn More -

-

Plastics & Composites

Plastics & CompositesMold cleaning time reduced by 50%, while labor reduced from multiple workers to one

Learn More

Plastics & Composites Dry Ice Cleaning Technology

Produce Higher Quality Parts by Cleaning Your Molds with Dry Ice Blasting

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.