Dry Ice Blasting for Adhesive Removal

Dry Ice Blasting Applications

A safer and more effective solution to adhesive removal

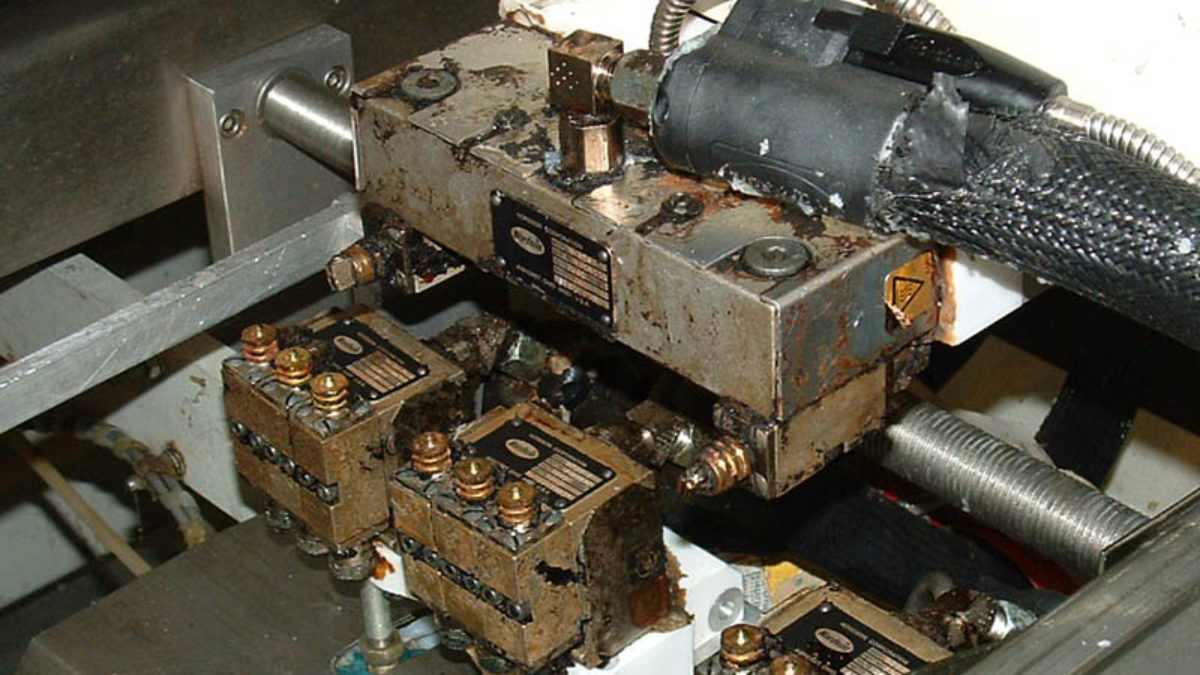

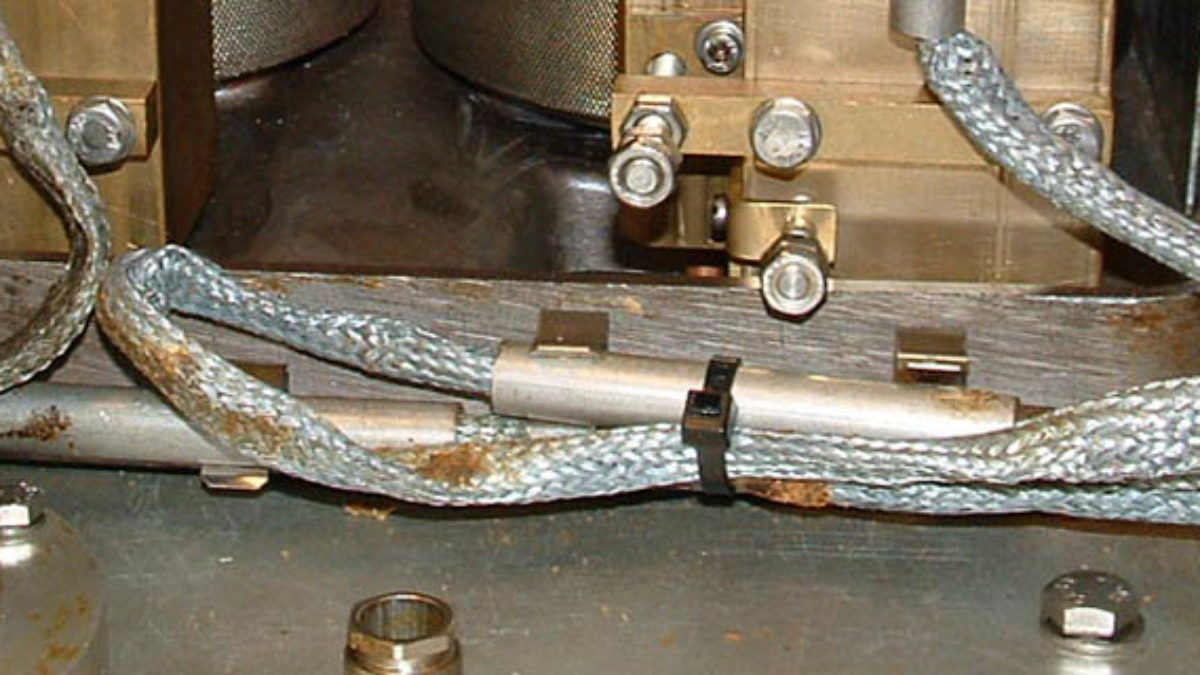

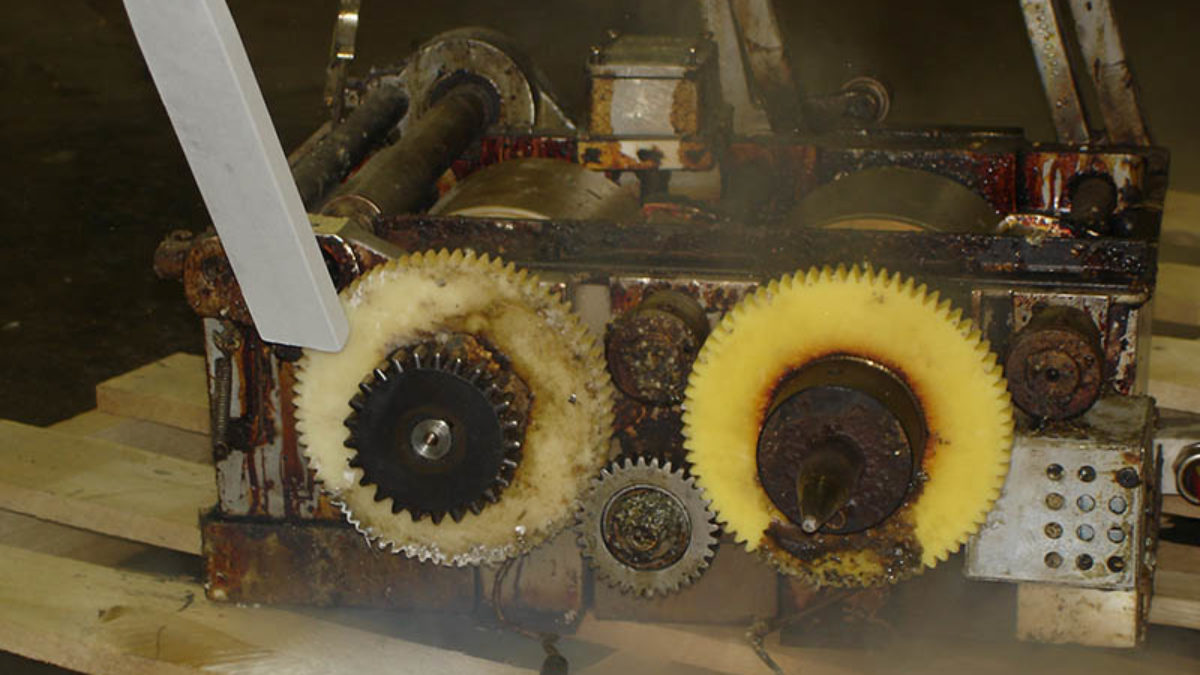

Dry ice blasting for adhesive removal is a quicker and more efficient solution to removing adhesive buildup on production equipment. The low temperature of dry ice weakens the bond between the adhesive and surface, enabling for a more effective removal. Dry ice blasting is non-abrasive and does not produce secondary waste, which leads to more regular cleaning and prolonged equipment life.

SPECIFIC USE CASES

Dry ice blasting effectively removes adhesives from a variety of equipment types in a wide range of industries

- Glue nozzles

- Cutter drums

- Glue assemblies

- Gripper drums

- Production and processing equipment

- Bag-in-box formers

- Labelers

- Weld lines

- Conveyors

- Ancillary equipment

- Hot melt adhesive removal

- +More

RELATED INDUSTRIES

Benefits of Dry Ice Blasting

Safely and quickly remove adhesives from production equipment, without harmful chemicals

Dry ice blasting eliminates abrasive and timely manual cleaning, while also prolonging equipment life and decreasing equipment replacement costs.

- Eliminate manual cleaning processes

- Prolong equipment life Significantly reduce replacement costs

- Reduce production downtime

- Improve product quality and decrease scrap rates

- Non-abrasive Will not damage equipment

- Eliminate caustic and harmful chemicals

- Reduce labor costs

- No secondary waste streams

- Environmentally sustainable

Adhesive Removal Dry Ice Cleaning Technology

Dry Ice is a Quick, Efficient Solution to Remove Burnt-on Glue

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.