With dry ice cleaning, the quality of our finished parts increased greatly. Power washing leads to varnishing and stains on the parts, while dry ice cleaning eliminates this.

Dry Ice CLeaning Equipment for Plastics Industry

Solutions for your pain points in plastics processing

Dry ice blasting helps plastic manufacturers reduce scrap and downtime, improve product quality, prolong the life of their equipment, and increase profitability.

Dry Ice Cleaning Equipment for Plastics & Composites

Dry ice blasting offers numerous benefits for cleaning in the Plastics industry, making it a great choice for companies looking to improve efficiency, quality, and sustainability in their manufacturing processes. When manufacturing plastic and composite parts, molds and equipment must be kept meticulously clean to ensure product quality. Dry ice blasting can effectively remove residues, mold-release agents, and contaminants from molds, extruders, and other equipment without damaging delicate surfaces.

Traditional cleaning methods like sandblasting or chemical cleaning can be abrasive and may damage plastic surfaces. Dry ice blasting provides a non-abrasive alternative, making it suitable for cleaning sensitive plastic components without causing any harm. Dry ice blasting involves propelling pellets of dry ice at a high velocity to clean surfaces. It’s non-toxic since dry ice is made of solid carbon dioxide (CO2), which sublimates (turns into gas) upon contact with the surface being cleaned, leaving no residue. Investing in the right dry ice blasting equipment is crucial for achieving optimal results.

View our selection of dry ice blasting equipment or contact our representatives today to learn which product would work best for your needs!

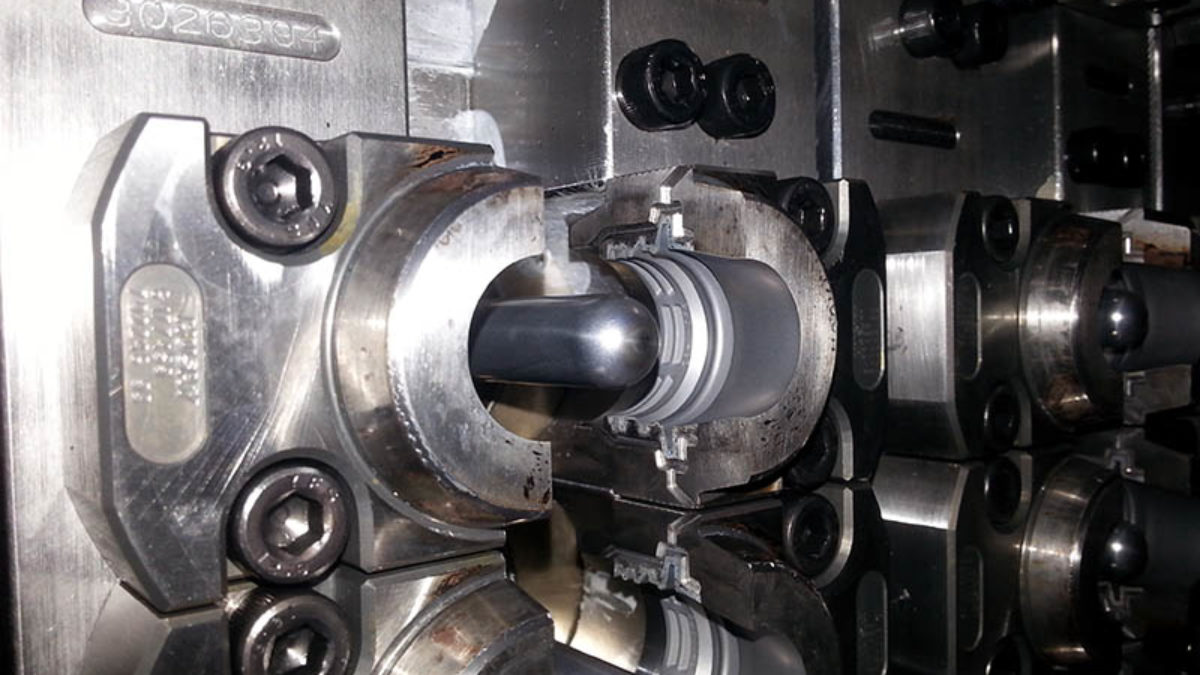

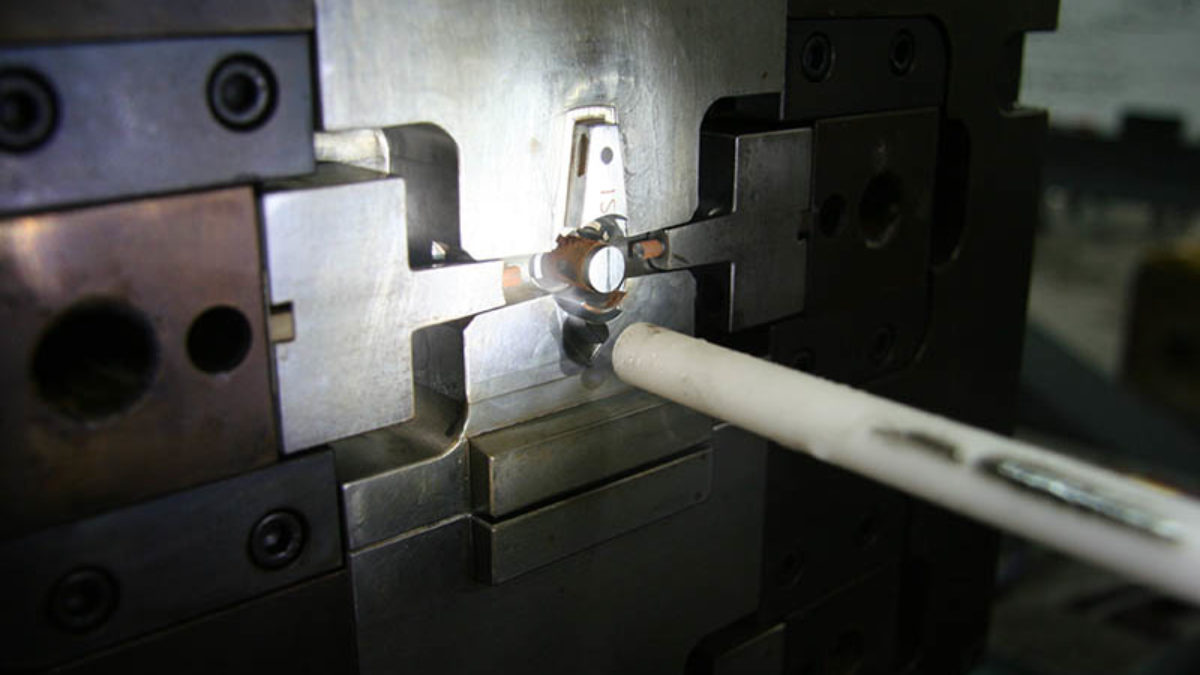

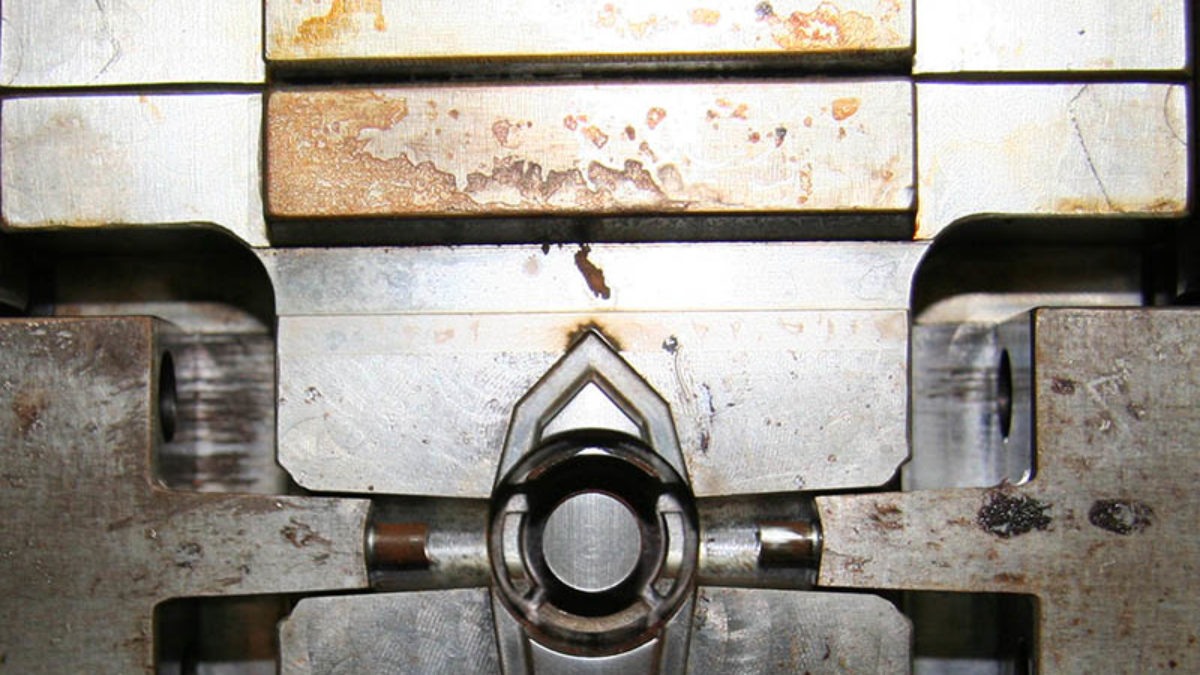

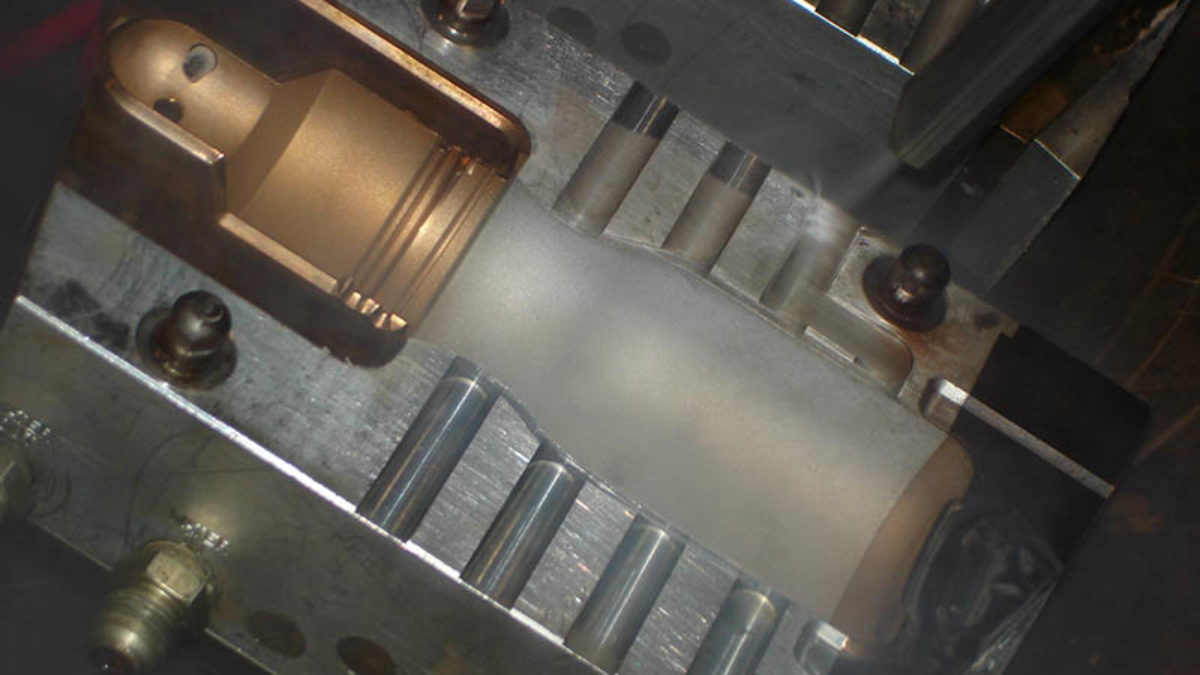

Mold Cleaning With Dry Ice Blasting

Cut downtime while improving part quality

Benefits

Dry ice cleaning provides a non-abrasive method to safely clean molds online at operating temperatures.

- Improve product quality

- Clean in-place Little to no disassembly required

- Non-abrasive No damage to molds

- Reduce scrap Cleaner molds lead to higher quality

- Reduce production downtime Clean quicker and without cooldown

- Decrease cleaning time and labor costs

- Eliminate painstaking manual cleaning

Specific use cases:

- Injection molds

- Blow molds

- Compression molds

- Urethane molds

- Textured molds

- Medical molds

- Technical molds

- Extrusion dies

- PET preform molds

- LSR and LIM molds

- +More

Surface Preparation

Prepare surfaces with a dry process that allows for immediate coatings/paint application

Benefits

Dry ice cleaning machines deliver a dry process that eliminates the need for aqueous or chemical solutions on paint lines.

- Dry process allows for immediate painting or coating after cleaning

- No secondary waste Reduce disposal costs

- Non-abrasive Will not damage parts

- Improve product quality

- Environmentally sustainable

Specific use cases:

- Interior automotive parts

- Exterior automotive parts

- Cleaning surfaces before RTV’s

- +More

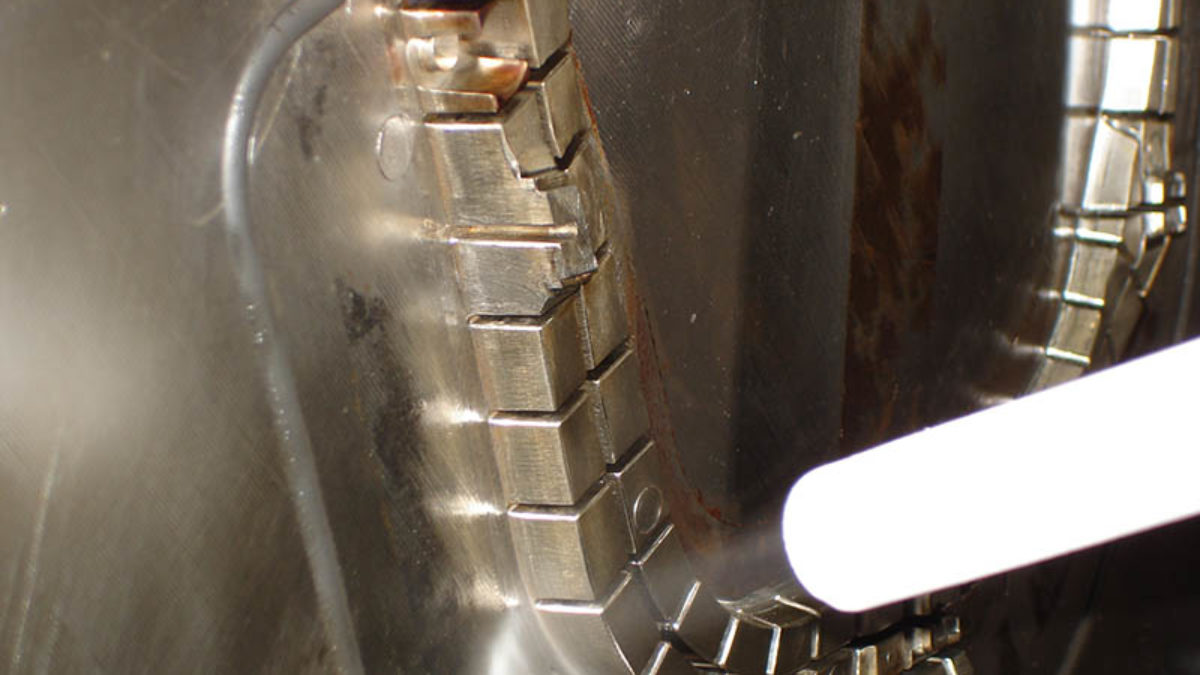

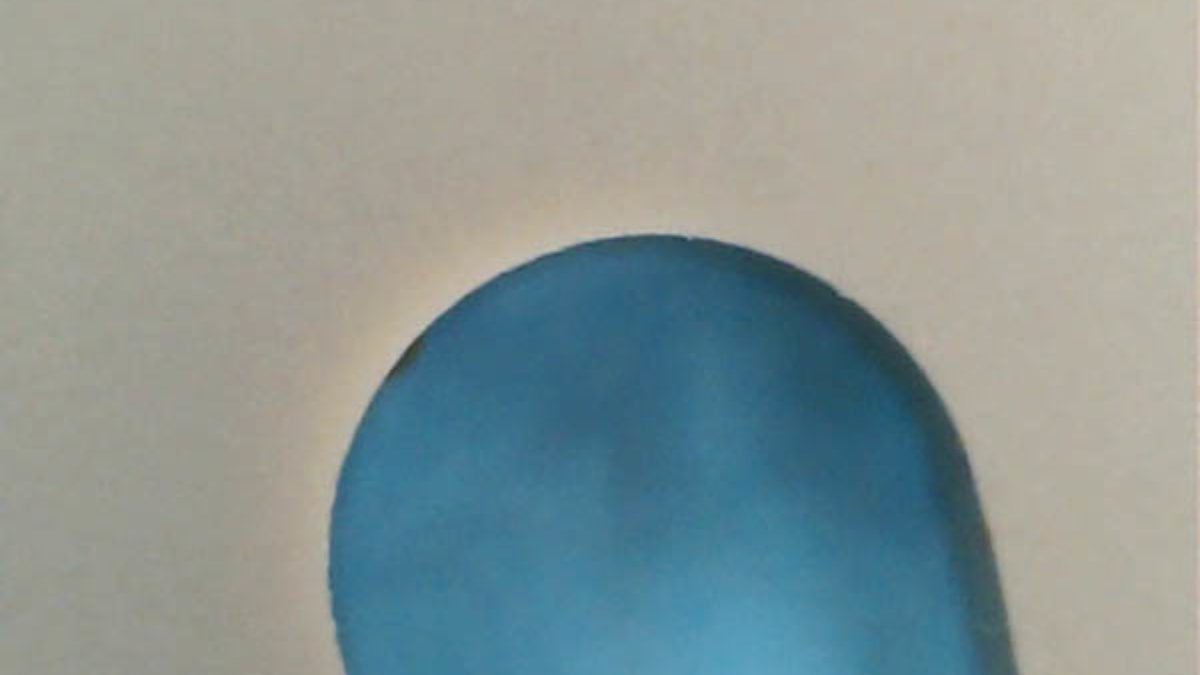

Parts Finishing

Quickly and safely deburr and deflash parts

Benefits

Dry ice blasting machines provide a faster and more uniform flash and burr removal process without causing damage to the part.

- Faster and more uniform clean

- Elimination of cross contamination

- Non-abrasive Lower scrap rates

- Reduce cleaning costs and overall downtime

- Higher quality parts

- Eliminate manual cleaning

Specific use cases:

- PEEK

- PBT

- Acetal

- Nylon

- LCP

- ABS

- UHMWPE

- Nitinol

- + More

Benefits of Dry Ice Blasting

Maintain high quality standards while improving productivity

The unique benefits of dry ice make it the perfect cleaning media for plastics processors.

- Improve part quality

- Reduce scrap

- Reduce production downtime

- Decrease cleaning time and labor costs

- Clean in-place No disassembly required

- Non-abrasive No damage to product or equipment

- Environmentally sustainableNo secondary waste

- Operationally safe Reduce harmful chemicals and tedious manual cleaning

Dry Ice Cleaning for Plastics

Cold Jet’s line of dry ice blasting machines can be used to remove the build-up of unwanted surface residues from either the product mix itself, mold releases, or the labeling process.

Case Studies

Proven technology produces definable results

Our solutions are driving real results in our customers’ organizations.

-

Plastics & Composites

Plastics & CompositesInjection molder reduced maintenance cycles by 50%, reducing costs and downtime

Learn More -

Medical Device

Medical DeviceMedical device manufacturers experience improved product quality and reduced scrap rates

Learn More -

-

Plastics & Composites

Plastics & CompositesMold cleaning time reduced by 50%, while labor reduced from multiple workers to one

Learn More

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.