Dry Ice Production Solutions

Simplify your cooling and processing operations with dry ice, which provides a safe, residue free and enhanced cooling solution. Discover Cold Jet dry ice production machines.

How can we support you?

Still learning about dry ice and dry ice production?

Dry Ice Production for Blasting

Whether you’re looking to manage your own dry ice supply for blasting, or you’re supplying dry ice to your customers, opting for bulk 3 mm dry ice pellets is the ideal choice.

Discover the dry ice pelletizer that suits your needs:

-

Make up to 176 lbs/hr (80 kg/hr)

PE 80 Dry Ice Pelletizer -

Make up to 264 lbs/hr (120 kg/hr)

PR120H Dry Ice Pelletizer -

Make up to 771 lbs/hr (350 kg/hr)

PR350H Dry Ice Pelletizer -

Make up to 1653 lbs/hr (750 kg/hr)

PR750H Dry Ice Pelletizer

What does that look like?

Infrastructure Needed Dry Ice Production – FAQ

Dry Ice Production for Sustainable Cooling

Dry ice comes in various forms for sustainable cooling: 3mm pellets, 10-16mm nuggets, or slices. Tell us what kind of perishable product you need to keep cold, and we’ll recommend the best dry ice format and production system for your needs.

What kind of perishable items do you need to keep cold?

-

In-flight meals.

Airline Catering -

Protein products, baked goods, and wine during processing.

Food Processing -

Frozen or chilled food during local or international shipping.

Food Transportation -

Temperature-sensitive life science products, such as pharmaceuticals, clinical trial samples, and cell and gene therapies.

Temperature Sensitive Therapies

What does that look like?

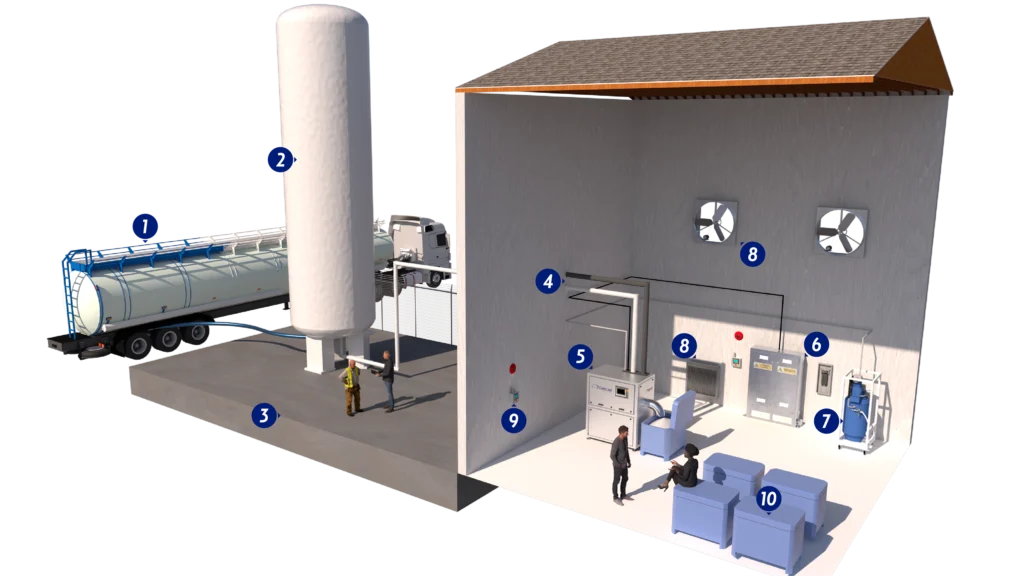

Infrastructure Needed for Dry Ice Production

To establish your own dry ice production,

you’ll need variations on the following infrastructure, depending on dry ice volumes:

- 1. Access to liquid CO2 in your region.

- 2. An on-site liquid CO2 reservoir.

- 3. A reinforced concrete foundation for stability.

- 4. Insulated pipe work to connect your exterior liquid CO2 reservoir to the dry ice production system.

- 5. A Cold Jet dry ice production system, protected from moisture and the elements, with plenty of room for production.

- 6. A three-phase electric power source for the Cold Jet dry ice manufacturing system.

- 7. A compressed air line.

- 8. Safety measures, including artificial ventilation to maintain airflow within the manufacturing facility.

- 9. A CO2 PPM monitor.

- 10. Insulated containers to store dry ice, minimizing sublimation.

What does that look like?

Exhaust CO2 Gas Recovery Systems for Dry Ice Production

Produce Greener Dry Ice – Utilize Liquid CO2 Twice! Cut down on dry ice production expenses by decreasing the ratio of liquid CO2 used to produce dry ice. Achieve more with less.

Carbon Capture Technology in Your Dry Ice Production Operations.

What does that look like?

Dry Ice production – FAQ

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.