Dry Ice Blasting Applications:

General Equipment Cleaning

Clean your equipment – Improve your operations

Dry ice blasting equipment cleans all types of production and ancillary equipment without damaging surfaces, creating secondary waste or harming employees or the environment.

SPECIFIC USE CASES

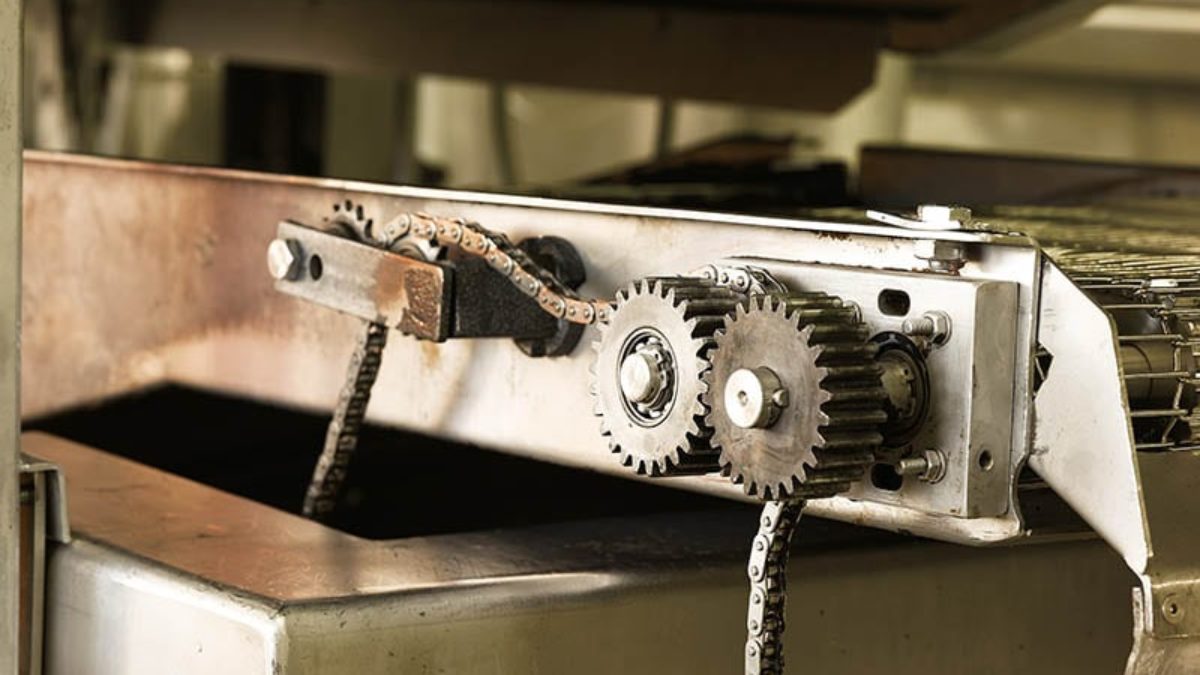

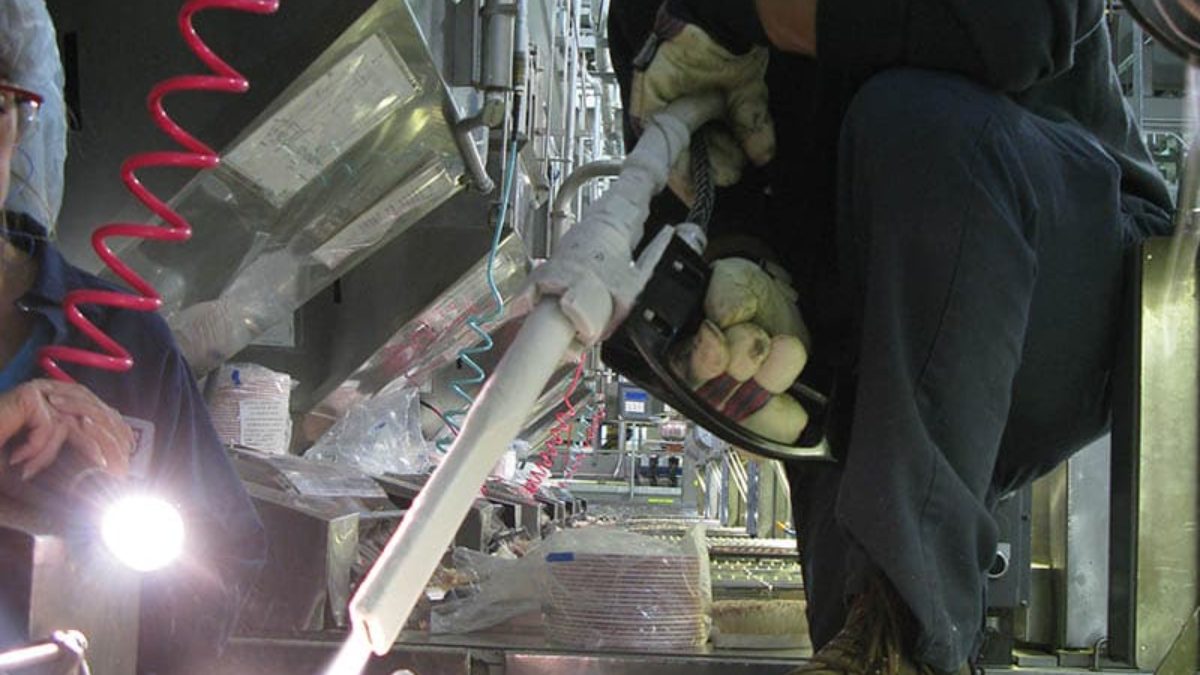

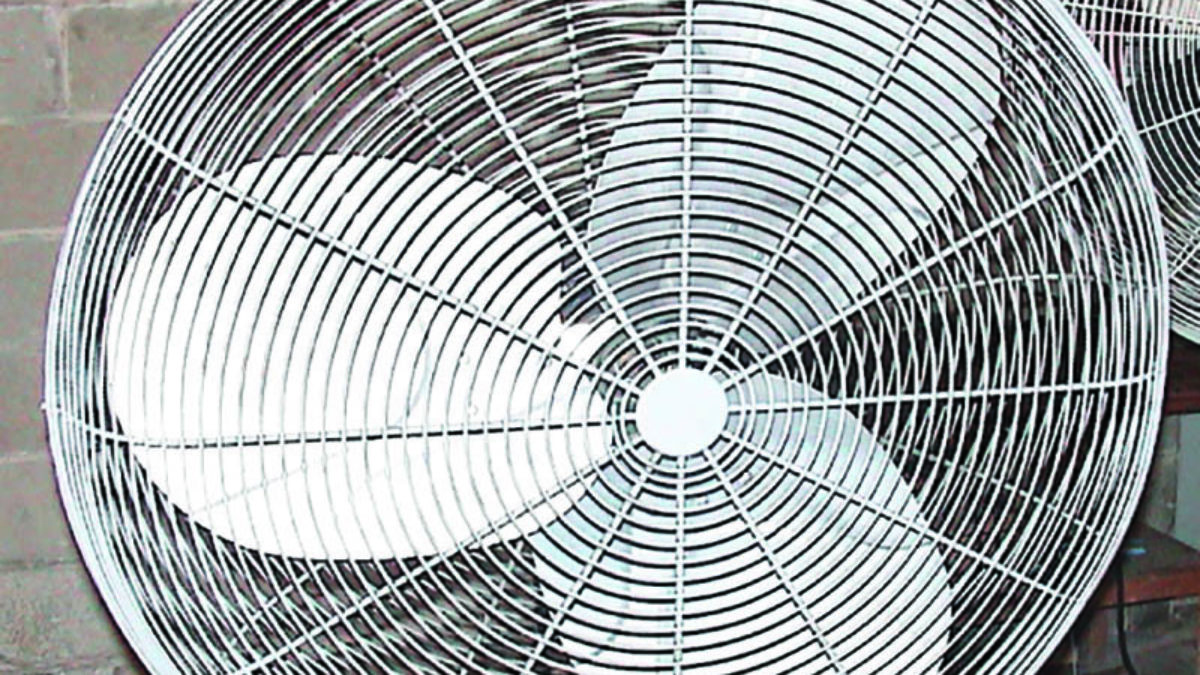

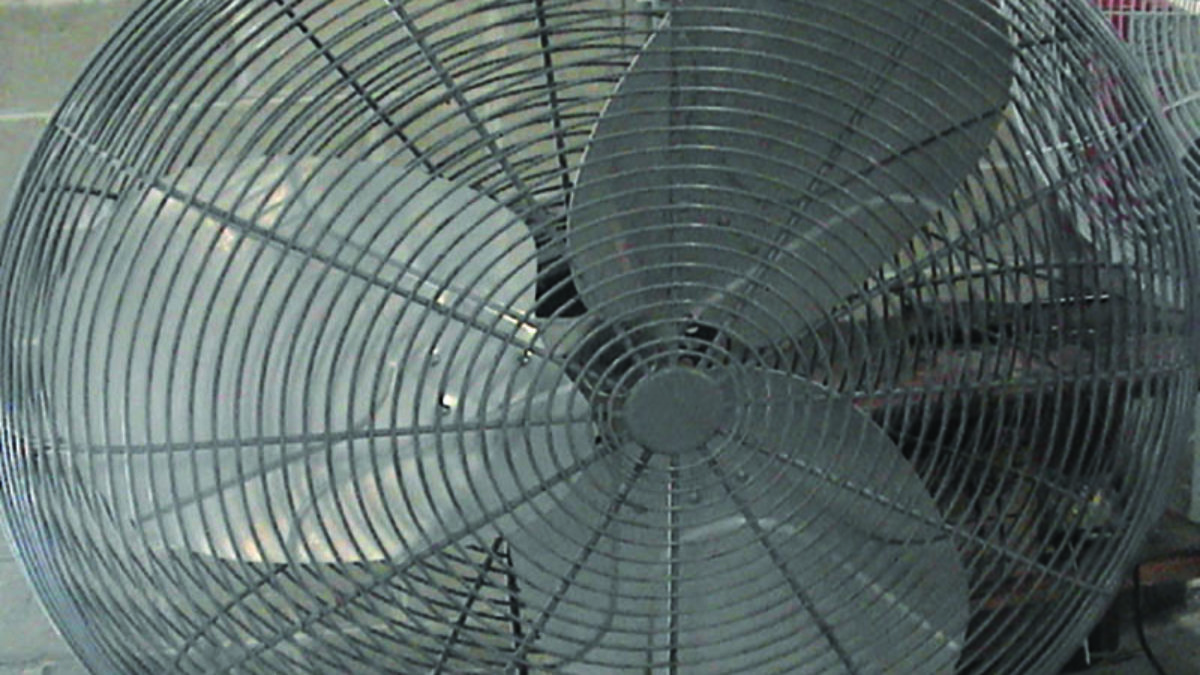

Dry ice blasting is an effective cleaning solution for all types of equipment and tooling

- Production equipment

- Ceilings and walls

- Equipment degreasing

- Surface cleaning before painting

- Forklifts

- Electric motors

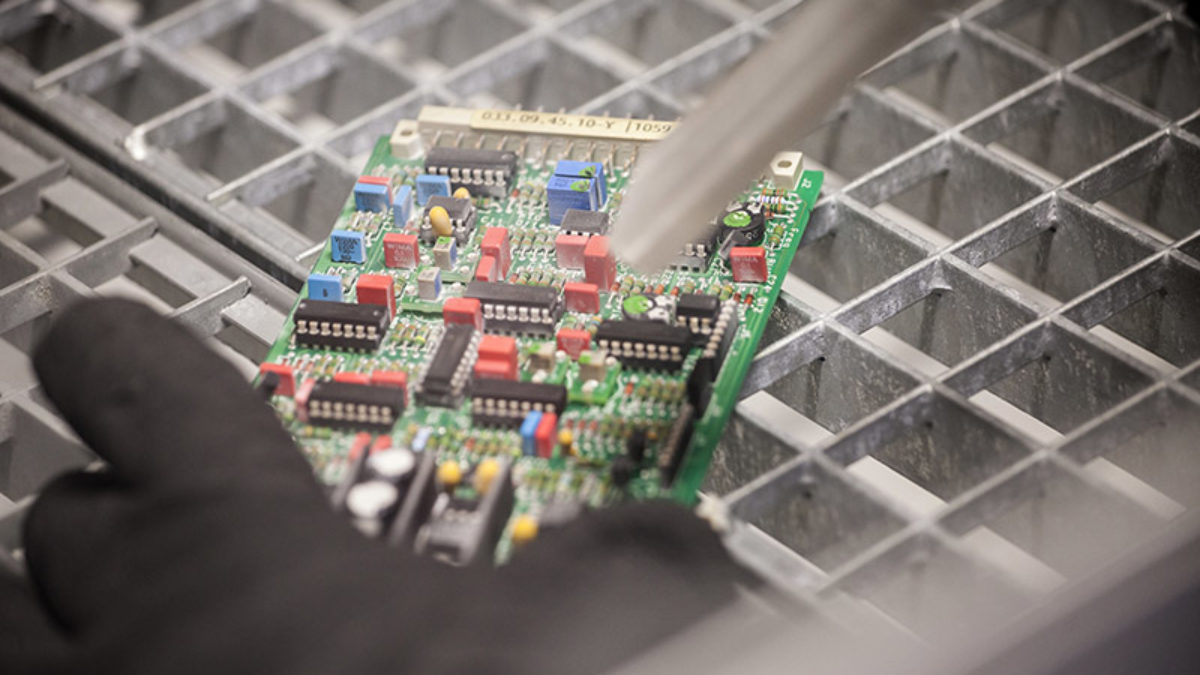

- Electrical boxes

- Control panels

- Pipes, hoses and fittings

- Conveyors

- Cooling fans

- Hydraulic parts

- Robotics

- Sanding belts

- +More

Benefits of Dry Ice Blasting

A clean surface is just one of the benefits

With dry ice blasting, you’re not just cleaning. You are improving your organization’s operations.

- Superior clean Clean more effectively than with traditional methods

- Clean in-place and online Reduce cleaning time and resulting downtime

- Non-abrasive No risk of damaging equipment

- Increase operational efficiency More efficiently allocate labor

- Environmentally sustainableEliminate water and chemicals from your sanitation processes

- Enhance operator safety Eliminate manual cleaning and exposure to unsafe conditions

- Improve part quality and reduce scrap Clean more often, resulting in high quality products

- Non-toxic and non-conductive

- Access and clean tight spaces

Case Studies

Dry ice blasting is improving our customers’ organizations

-

Food & Beverage

Food & Beverage -

Food & Beverage

Food & BeverageChocolate facility reduces cleaning time by 60%, while reducing maintenance costs and downtime

Learn More -

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.