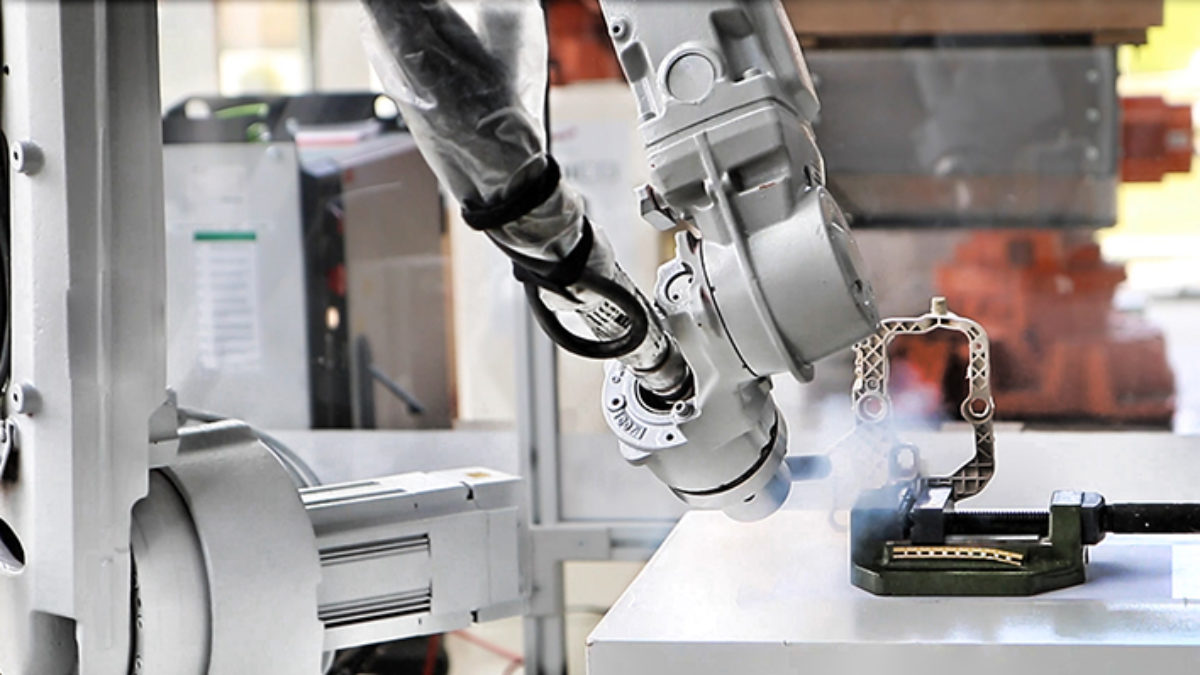

Dry Ice Blasting for Parts Finishing

Dry Ice Blasting Applications

Dry ice blasting is a faster and more uniform solution to parts finishing

Dry ice blasting for parts finishing is an effective solution to remove burrs and flash from machined and molded parts. Cleaning with dry ice is non-abrasive and does not create secondary waste, which ensures the geometries of the finished part are maintained without leaving residual media.

SPECIFIC USE CASES

Dry ice blasting safely removes flash and burrs from parts made from a variety of materials

- PEEK

- PBT

- Acetal

- Nylon

- LCP

- PP

- ABS

- UHMWPE

- Nitinol

- Acrylic

- Phenolic

- +More

RELATED INDUSTRIES

Benefits of Dry Ice Blasting

Improve part quality, while reducing operating costs

Dry ice cleaning eliminates manual deburring and deflashing processes, leading to higher quality finished parts in a fraction of the time.

- Non-abrasive Will not damage part geometry

- Improve product quality and decrease scrap rates

- Eliminate manual deburring and deflashing

- No secondary waste Eliminate risk of grit entrapment

- Deburr and deflash faster and more uniformly

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.