We were impressed with its ability to clean the contaminants from the printer safely, which also minimized our need to use chemicals.

Dry ice blasting equipment for Packaging

Dry Ice Blasting Machines for Packing & Production Equipment

Our dry ice blasting solutions for production equipment thoroughly clean buildup, such as adhesive, ink, grease, paper dust, labels, and food residue from packaging equipment in-place, while running, enabling facilities to maximize control and production efficiency.

Packaging Equipment Cleaning

Quickly clean buildup from production equipment without timely disassembly

Benefits

Dry ice cleaning increases productivity by eliminating unpredictable downtime caused by dirty, hard-to-clean packaging equipment.

- Clean hot and online

- Reduce cleaning time and resulting downtime

- Reduce risk of unplanned production stoppages and costly repairs

- Eliminate manual cleaning with harmful chemical solvents, wire brushes and scrapers

- No secondary waste

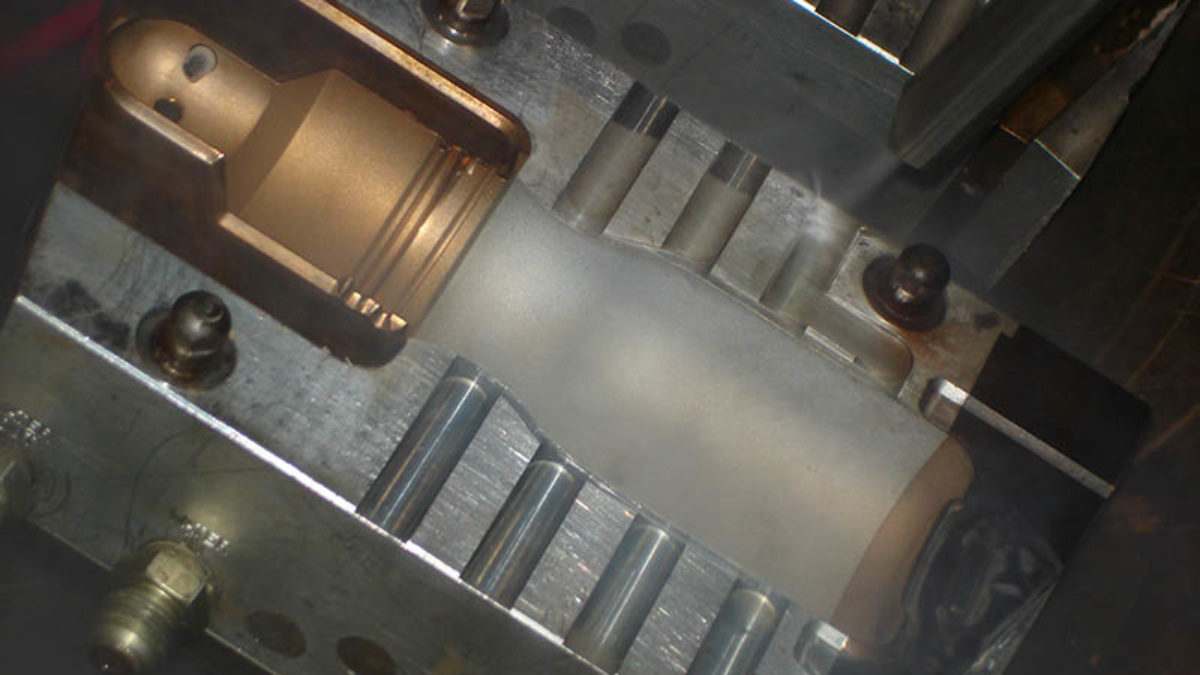

- Non-abrasive Clean sensitive equipment without damage

- Environmentally sustainable

Specific use cases:

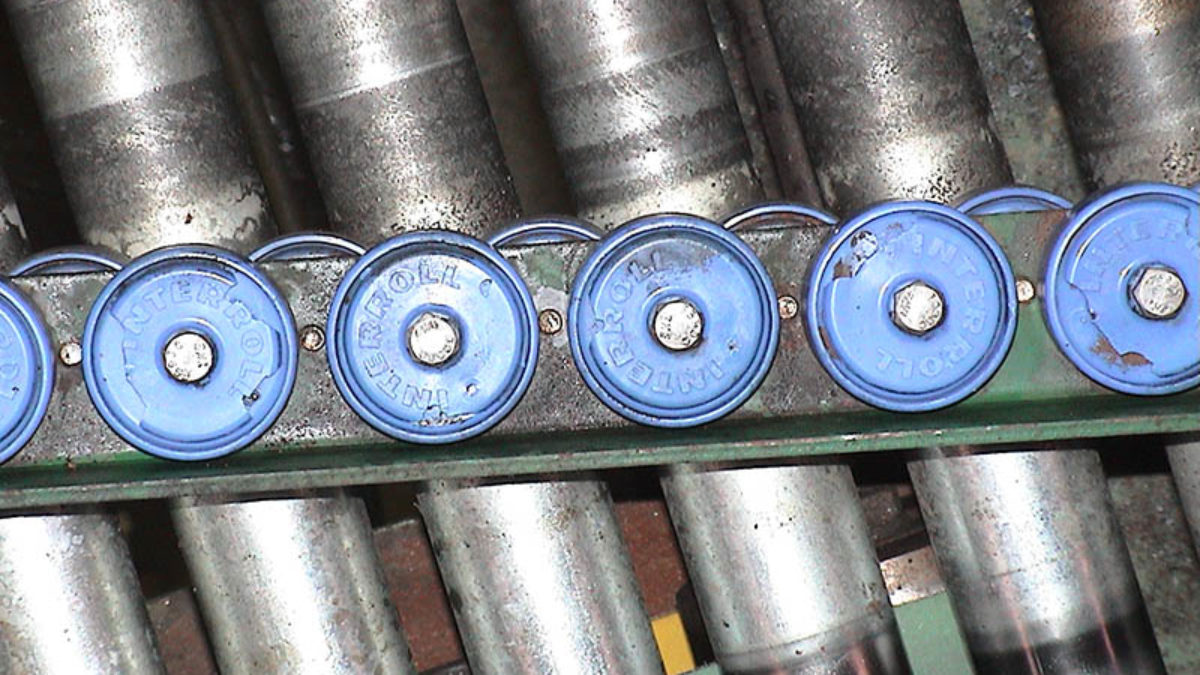

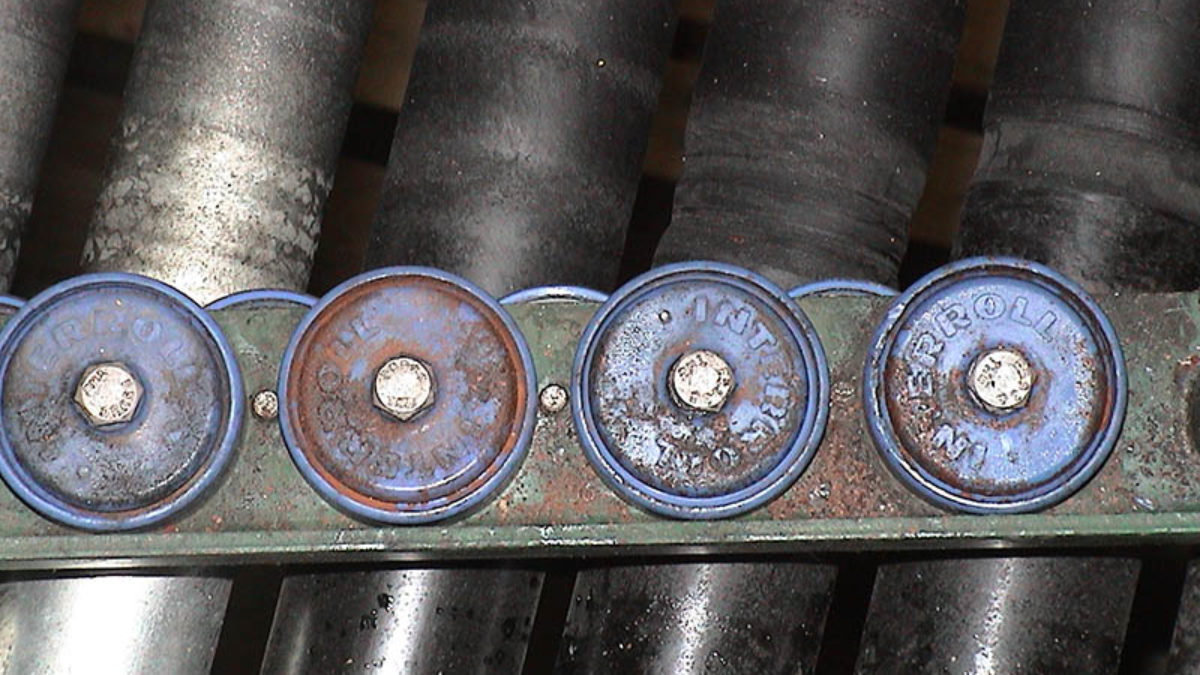

- Conveyors and airveyors

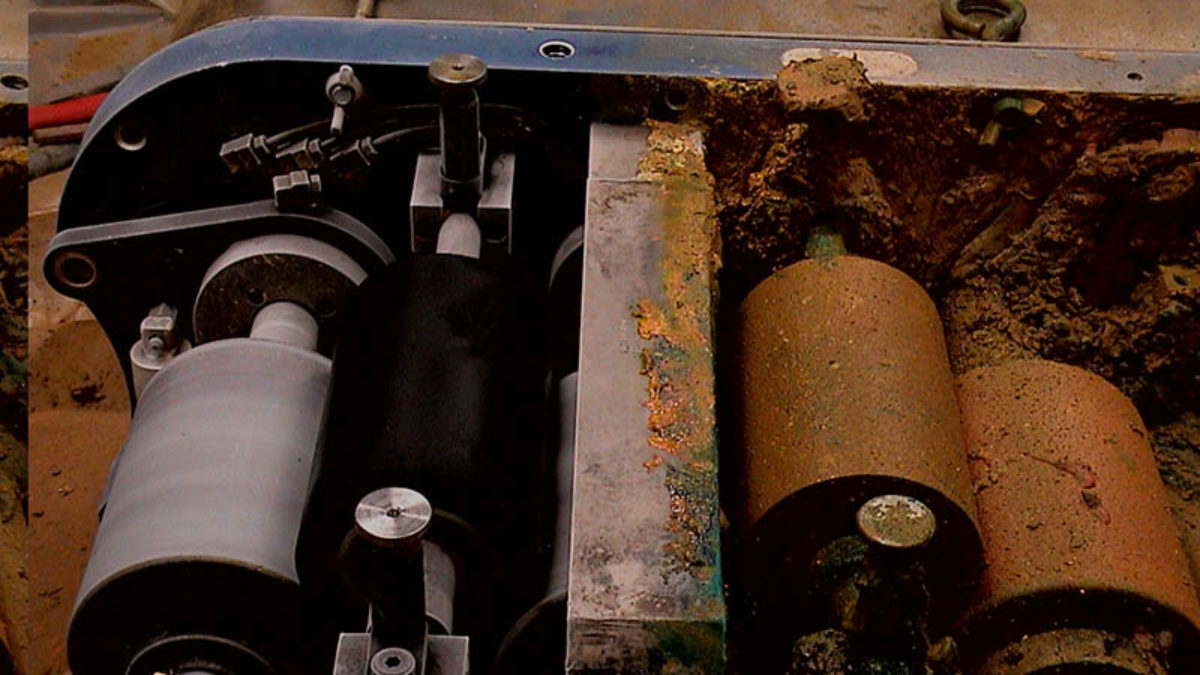

- Rollers and chains

- Baggers

- Pack-off tables

- Bag and box formers

- Corrugator Machinery

- Glue applicators and labelers

- Tape applicators

- Printers

- Presses and embossers

- Dryers

- Palletizers and de-nesters

- Radial feeders (Ishida weighers)

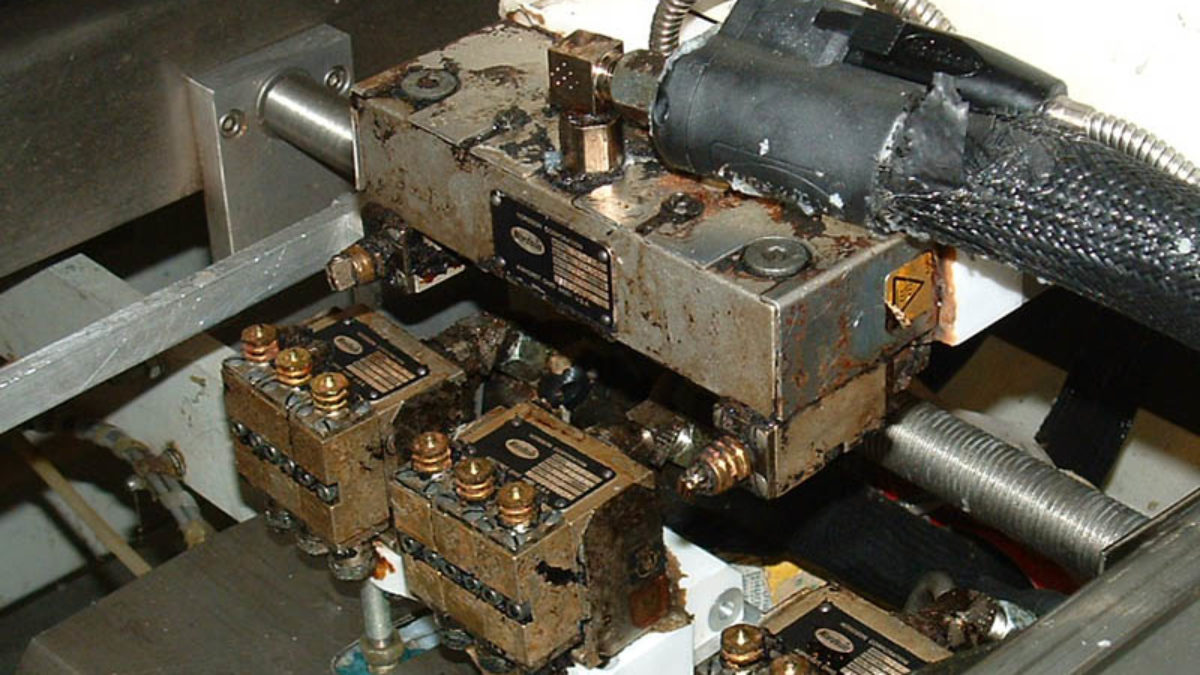

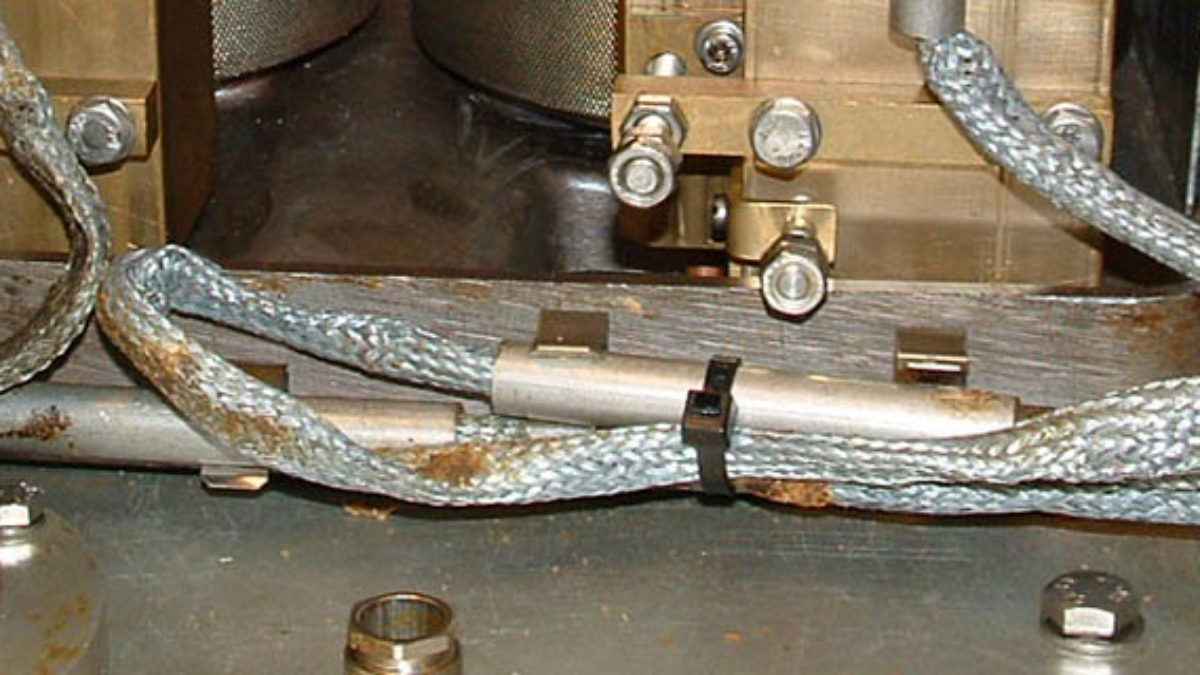

- Electrical components and motors

- Drive Belts

- +More

Benefits of Dry Ice Blasting

Clean predictably and effectively while reducing downtime, manual cleaning and scrap rates

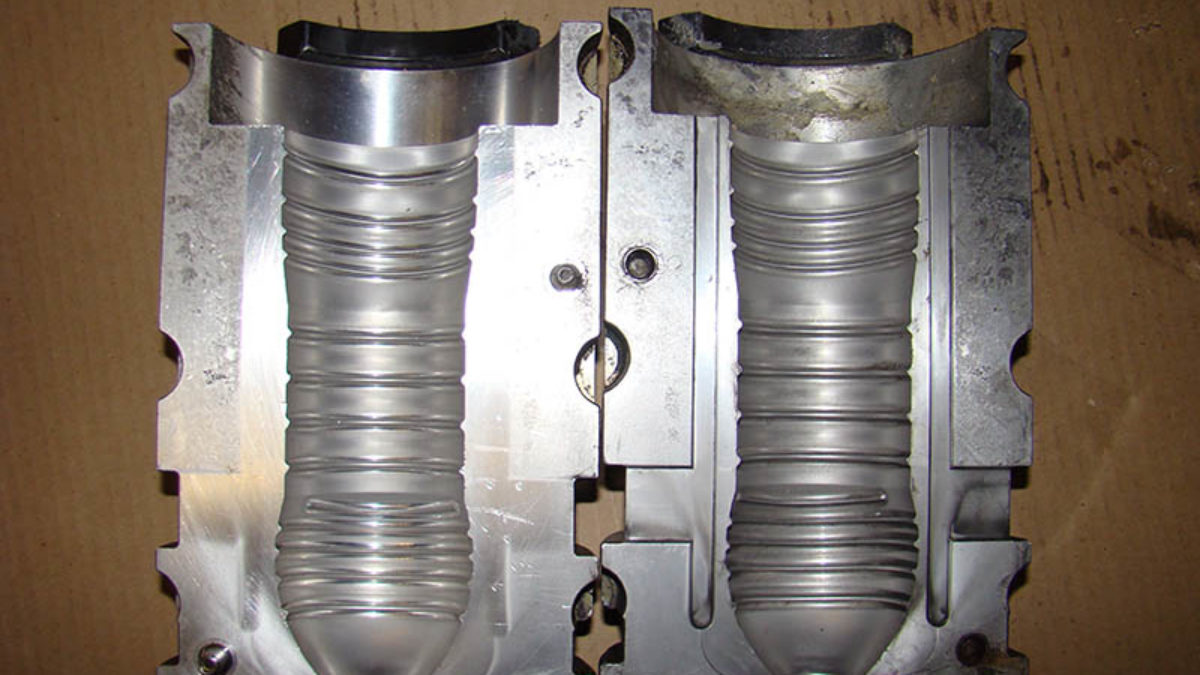

Dry ice cleaning provides a quick, safe and economical solution to clean tooling and equipment, resulting in less downtime, a better clean, less rejected parts, improved tool utilization and longer asset life.

- Clean online or in place, even while equipment is hot and running

- Eliminate unpredictable manual cleaning

- Reduce risk of unplanned production stoppages and costly repairs

- No water or harmful chemicals

- Non-conductive Clean electronics, sensors and motors without damage

- No secondary waste streams

- Reduce labor costs

- Reduce scrap rates

- Non-abrasive Will not damage equipment

- Environmentally sustainable

- Operationally safe Eliminate manual cleaning and exposure to unsafe conditions

Case Studies

Proven technology produces definable results

Our solutions are driving real results in our customers’ organizations.

Dry Ice Cleaning Technology for the Packaging Industry

Cold Jet’s line of dry ice blasting machines can be used for packaging applications including dry ice blasting equipment for coating lines.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.