Dry ice production in food processing facilities

Inhibit Microbial Growth, Regulate Fermentation & Prevent Oxidation With a More Sustainable Cooling Solution.

Dry Ice is a food approved cooling medium that ensures critical control points (CCPs) are met, during the production, storage and transportation of chilled and frozen products.

The Magic of Dry Ice in Food Processing Cooling

Expand your knowledge of dry ice in food processing by downloading our Magazine.

The temperature of dry ice measures (-109 °F / -78.5 °C) and its cooling power is thrice that of water-formed ice. Microbial activity is inhibited below 40 °F (4 °C).

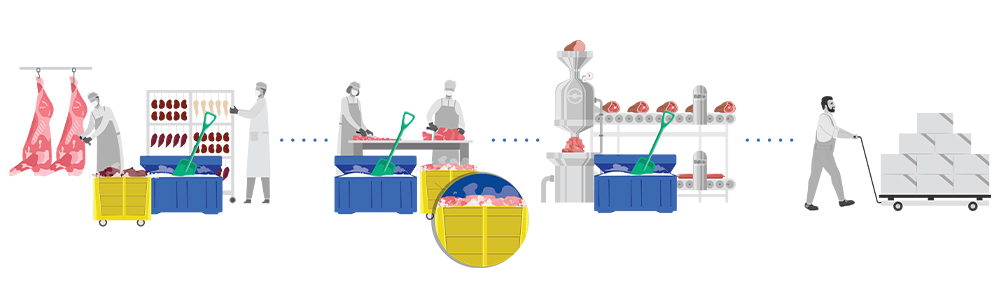

Dry Ice Cooling in Meat Processing

Dry Ice has a primary function of transferring cold energy into your product. It aids in maintaining critical temperatures, preventing hot spots and therefore curbing microbial growth without adding water to the process.

Benefits

Dry ice enhances meat product quality, safety, and production efficiency, reducing the risk of contamination and lowering production costs in the process.

- Eliminate hot spots

- CAPEX PREVENTION No need to invest in additional chiller cooling capacity infrastructure

- Reduced weight Dry ice pellets are much lighter than water

- Reduce product rejects

- Rapid chilling & freezing

- Reduce drip loss

- Inhibit microbial growth

- Environmentally sustainable

Specific use cases:

- Offal Lines

- Trim Lines

- Mixers & Blenders

- Added Value Shipping

- Intermodal Transportation Cooling

- Dry Ice Blasting on Food Equipment

- +More

Ideal dry ice production equipment for meat processing facilities:

-

The PR750H Dry Ice Pelletizer.

Produce up to 1,653 lbs (750 kg) per hour

PR750H -

The PR350H Dry Ice Pelletizer.

Produce up to 772 lbs (350kg) per hour

PR350H -

Automated Dry Ice Production & Dosing

Custom-engineered for intermodal food transportation and meat chilling. These machines create precise dry ice slices and pellets and accurately drops them directly into a conveyor of boxes. The perfect addition to your fully automated food processing system.

DS1000E

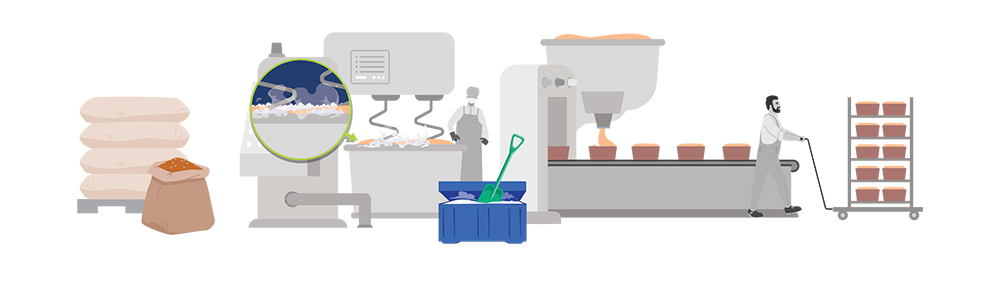

Dry Ice Cooling in Industrial Baking

Similarly, within the industrial bakery sector, it plays a crucial role in temperature and fermentation control leading to batch consistency.

Benefits

Dry ice pellets are the perfect solution for chilling dough in bakery plants. By keeping yeast cool in mixers and blenders, you can control fermentation, even during hot weather. This makes dry ice a valuable tool for bakery managers, operations directors, and food safety and quality professionals.

- Inhibit microbial growth

- Prevent fermentation

- Maintain batch consistency

- Environmentally sustainable

Specific use cases:

- Dough Mixers

- Dough Blenders

- +More

Ideal dry ice production equipment for industrial bakery facilities:

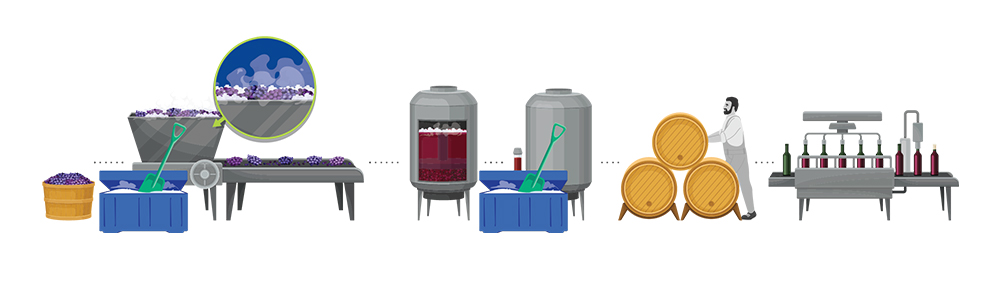

Dry Ice Cooling in Winemaking

Meanwhile, in winemaking within the beverage sector, dry ice is instrumental in protecting the must from oxygen and to support temperature control.

Benefits

Dry ice During fermentation, dry ice pellets are often added to fermentation vessels to protect the must from oxygen and to support temperature control; 3 mm dry ice pellets are ideal for this application.

- Protects the grapes from the heat

- Protects the must from oxygen

- Maintains wine batch consistency

Specific use cases:

- Grape Harvest Chilling

- Fermentation Tanks

- +More

Ideal dry ice production equipment for winemaking sites:

-

Dry Ice Production Hub.

Our compact, modular dry ice unit, housed in a 10 x 10 ft (3 x 3 m) ISO container, allows you to produce dry ice anywhere. Position it alongside your liquid CO2 source and watch it efficiently produce dry ice on-demand.

Dry Ice Production Hub -

The PR120H Dry Ice Pelletizer.

Produce up to 265 lbs (120kg) per hour

PR120H -

The PE 80 Dry Ice Pelletizer.

Produce up to 176 lbs (80 kg) per hour

The PE 80 – A Low-Volume Dry Ice Pelletizer

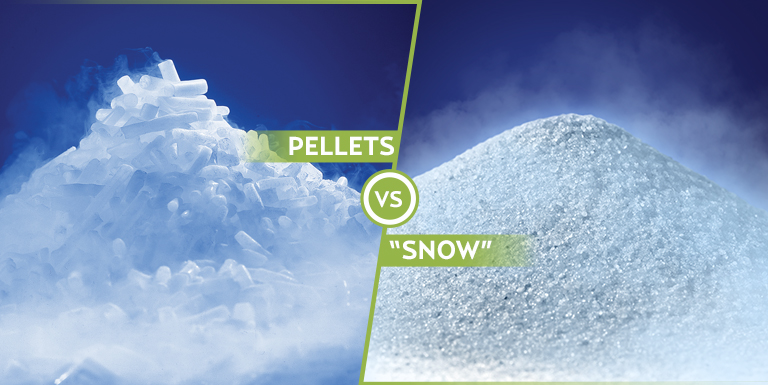

Dry Ice as a Cost-Effective Alternative to CO2 Snow

The CO2 snow horn is a widely used device in the meat industry and other food processing industries as a method to flash freeze product by covering it quickly with a layer of carbon dioxide “snow”.

CO2 snow horns require approximately 70% more liquid CO2 compared to a Cold Jet pelletizer, in order to produce an equivalent amount of solid CO2 dry ice.

| Cooling Method | LCO2 Conversion Ratio | Safety | Product Scrap |

|---|---|---|---|

| Dry Ice | Low Conversion Ratio (2.2 to 1) | Minimum CO2 Vapor | High-Density Pellets Extruded |

| CO2 Snow | High Conversion Ratio (4.5 to 1) | Creates Large Amounts of CO2 Vapor | Product Lost Due to High Exhaust Requirements |

When food safety is on the line, processors trust in Cold Jet.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.