Dry Ice Blasting & Production Technology Resources

Your source for dry ice solutions

Cold Jet invented modern dry ice technology. We are the leaders in the industry and the global experts. We offer the most extensive and informative library of dry ice blasting and production technology resources in the industry.

Videos

See our dry ice solutions in action

Case Studies

Read about how our customers found success with dry ice solutions

-

-

Contract Cleaning

Dry ice blasting removes graffiti in a matter of minutes in Malta

Learn More Case Study -

Restoration & Remediation

Dry Ice Blasting Provides Authentic Presentation When Restoring Classic Cars

Learn More Case Study

News

Keep up with the latest in dry ice technology

-

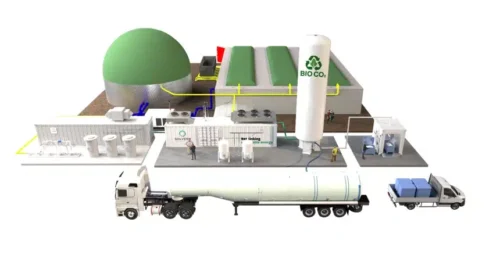

Cold Jet and Solveno Technologies Partner to Deliver Turnkey CO₂ Capture and Utilization Solutions for the Biogas RNG Market

Learn More News -

-

White Papers

Our white papers give an in-depth examination of dry ice solutions in various industries from experts in the field.

Webinars

Watch a webinar for an in-depth understanding of select dry ice technology topics.

-

-

-

Contract Cleaning

Getting Started with Dry Ice Blasting: A Guide for Contract Cleaners

Learn More Webinar

Educational Materials

Read more information specific to your industry or application.

-

-

Rubber & Tires

Q&A: Utilizing Dry Ice for Decontamination of Rubber Parts and Tooling

View PDF Educational Material -

Product Resources

Find out more about our dry ice solutions products by downloading our spec sheets, brochures and catalogs.

- Smart Dry Ice Blasters

- Pellet Dry Ice Blasters

- MicroParticle Dry Ice Blasters

- Specialty Dry Ice Blasters

- Pelletizers

- Reformer

- Integrated Blasting Systems