Cold Jet has greatly increased our efficiency with core box cleaning.

Dry Ice Blasting for Foundries

Reduce downtime while protecting foundry equipment from damage

Dry ice blasting for foundries significantly reduces cleaning time of permanent molds, core boxes, die cast tooling and ancillary equipment while improving part quality.

Mold Cleaning

Increase product quality and reduce scrap rates by eliminating coating irregularities and buildup

Benefits

Dry ice blasting completely removes refractory coating and residual material without damaging mold vents or rounding mold edges.

- Improve product quality

- Clean in-place Little to no disassembly required

- Non-abrasive No damage to surface area or vents

- Reduce scrap Cleaner molds lead to higher quality

- Meet stringent industry demands 6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance)

- Reduce production downtime Clean quicker and without cooldown

- Decrease cleaning time and labor costs

- Eliminate painstaking manual cleaning

Specific use cases:

- Permanent aluminum molds

- Shell core molds

- Casting molds

- Thermoform molds

- RIM urethane molds

- Permanent grey iron molds

- Metal bonded molds

- Injection molds

- Compression molds

- +More

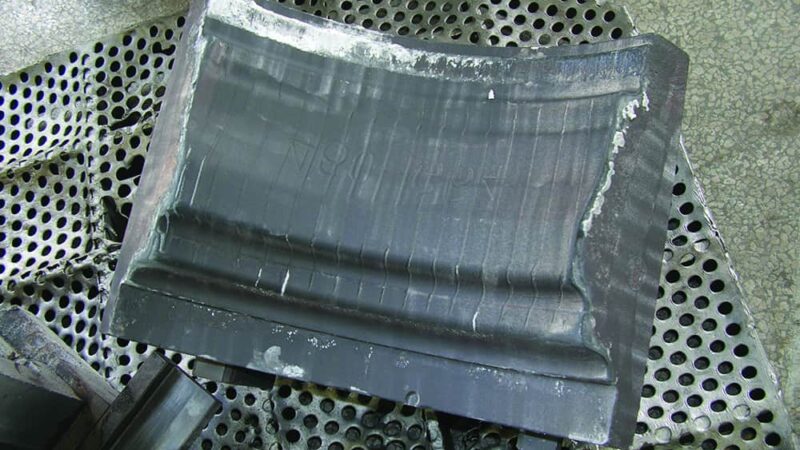

Core Box Cleaning

Significantly reduce cleaning time without damaging vents

Benefits

Dry ice cleaning quickly and safely removes buildup of sand, resin and other residue without damaging core boxes.

- Reduce production downtime

- Safely clean without damaging vents or screens

- Eliminate disassembly Clean while hot and in-place

- Clean more effectively

- Eliminate waste disposal costs

- Environmentally sustainable

- Deliver superior as-cast finish

Specific use cases:

- Cold boxes

- Half core boxes

- Dump core boxes

- Split core boxes

- Strickle core boxes

- Left and right hand core boxes

- Loose piece core boxes

- Gang core boxes

- +More

Die Cast Tooling Cleaning

Effectively clean forging dies while hot and online

Benefits

Dry ice blasting effectively removes scale, oxides and lubricants from die cavities without damaging equipment.

- Improve product quality

- Reduce production downtime

- Clean quicker and without cooldown or disassembly

- Non-abrasive No damage to equipment

- No secondary waste

- Eliminate painstaking manual cleaning

- Delivers superior as-cast finish

- Environmentally sustainable

Specific use cases:

- Semi-solid casting tooling

- Squeeze casting tooling

- Low-pressure permanent molding (LPPM)

- Permanent molding

- +More

General Equipment Cleaning

Reduce cleaning time and production downtime while prolonging equipment life

Benefits

Dry ice cleaning quickly and effectively cleans foundry production equipment without water, chemicals or secondary waste.

- Reduce cleaning time

- Eliminate manual cleaning with harmful chemical solvents

- Enhance Total Productive Maintenance (TPM) programs

- No secondary waste

- Non-abrasive Eliminate wear and tear on machinery

- Reduce risk of unplanned production stoppages and costly repairs

- Environmentally sustainable

- Clean in-place

Specific use cases:

- Metal processing equipment and tooling

- Equipment degreasing

- Refractory coating removal

- Coating equipment

- Hydraulic power units

- Electric motors and electric boxes

- Resins and release agents removal

- Ceilings and walls

- Control panels

- Cooling fans

- Pipes, hoses and fittings

- +More

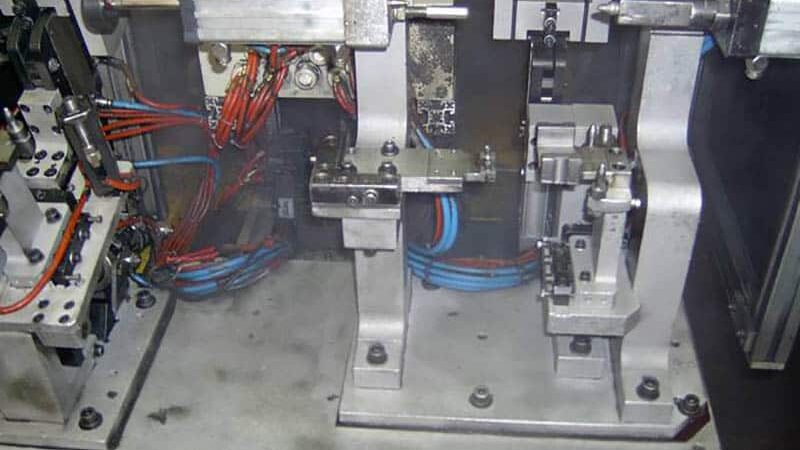

Weld Line Cleaning

Improve efficiency and accuracy of automated weld lines

Benefits

Dry ice cleaning eliminates weld line misalignment, breakdowns and scrap by effectively removing weld slag and spatter buildup.

- Reduce scrap rates

- Maximize tooling life and decrease fixture repair

- Non-abrasive Will not damage sensors

- Replace ineffective, costly and labor intensive cleaning methods

- Minimize downtime

- No secondary waste

- Environmentally sustainable

- Clean onlineNo cooldown required

Specific use cases:

- Robot joints

- Transfer cases

- Shuttle jigs

- Diamond plates

- Trunnions

- Weld tables

- Fixtures

- Proximity switches

- +More

Benefits of Dry Ice Blasting

Increase equipment productivity and the quality of finished parts

Dry ice blasting effectively and safely cleans permanent molding and die casting equipment without the need for disassembly.

- Increase productivity and reduce downtime

- Clean in-place No disassembly required

- Decrease cleaning time and labor costs

- No secondary waste stream for disposal

- Improve part quality and reduce scrap

- Delivers superior as-cast finish

- Non-abrasive No damage to product or equipment

- Operationally safe Reduce harmful chemicals and tedious manual cleaning

- Environmentally sustainable

Case Studies

Proven technology produces definable results

Our solutions are driving real results in our customers’ organizations.

Dry Ice Cleaning Technology for the Foundry Industry

Cold Jet’s line of dry ice blasting machines can be used in the foundry industry.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.