Dry ice blasting is a very effective method to remove the contaminant from the tools and even helps when burnings occur. From certain coatings, we could reduce maintenance cycles up to 50%; therefore, the costs and downtime were reduced considerably.

Dry Ice Cleaning Modernizes Maintenance Strategies for OEMs And Tier 1 Suppliers

This page details how Cold Jet’s dry ice blasting machines optimize cleaning and maintenance throughout the entire automotive production chain. By replacing slow, manual processes with our non-abrasive, sustainable solution, manufacturers achieve the following measurable operational results:

-

- OEE & Uptime Optimization: Cold Jet machines clean equipment in-situ (online) and at operating temperatures. By eliminating cooldown and disassembly time, facilities reduce overall cleaning time by up to 75%.

- Scrap Rate Reduction: The process completely removes residues—including release agents, weld spatter, and overspray—to eliminate surface defects, reducing scrap rates by 50–70%.

- Asset Life Extension: Using non-abrasive solid CO2 media, the process cleans without damaging sensitive sensors, mirror-finish molds, or electrical components, extending tooling life by 2–3x.

- Universal Application: Dry ice cleaning is a single solution that addresses challenges across the plant, including plastic and rubber molds, robotic weld cells, paint booths, foundry tooling, and paint and coating lines.

- Sustainability & Compliance: Dry ice sublimates upon impact, eliminating secondary waste streams and hazardous chemical solvents. This ensures compliance with OSHA safety standards and reduces disposal costs.

Ready to eliminate production bottlenecks? Contact us today to learn how Cold Jet dry ice cleaning machines optimize OEE and transform your manufacturing processes.

Measurable Benefits of Dry Ice Cleaning in Automotive Manufacturing

Dry ice cleaning machines deliver measurable improvements in Overall Equipment Effectiveness (OEE), product quality, and tooling lifecycle.

Automotive manufacturers achieve significant operational improvements with dry ice blasting. Whether maintaining injection molds, cleaning welding fixtures, or cleaning die cast tooling, Cold Jet dry ice blasting machines enable faster cleaning times with superior results. Dry ice cleaning dramatically reduces downtime, improves part quality, and eliminates the safety hazards associated with manual cleaning and chemical solvents.

-

Maximize Uptime by Streamlining Maintenance

Cold Jet dry ice cleaning machines streamline maintenance schedules in automotive facilities. The process cleans most equipment in-line and at operating temperatures without the need for disassembly or cool down. By reducing cleaning time by up to 75%, automotive manufacturers gain additional production slots daily with dry ice cleaning.

-

Extend Asset Life with the Non-Abrasive Process

Dry ice cleaning is non-abrasive, safeguarding sensitive equipment including plastic molds, welding clamps and sensors, electrical control panels, and robotic components. Facilities report equipment lifespan extensions of up to 2–3x with dry ice blasting. The process preserves critical tolerances on die casting tools, maintains mirror finishes on plastic molds, and safeguards delicate proximity switches on welding fixtures.

-

Boost Part Quality and Cut Scrap Rates

Dry ice blasting is critical for achieving consistently clean equipment and process reliability. It thoroughly removes all production residue, including weld spatter, overspray in paint booths, and off-gas or release agents. Dry ice blasters enable more frequent and more effective cleaning and maintenance, directly resulting in consistent, high-quality production. Automotive manufacturers implementing dry ice cleaning frequently report dramatic scrap rate reductions of 50–70%.

-

Eliminate Secondary Waste and Cut Disposal Costs

Dry ice blasting is a dry process that completely eliminates secondary waste streams. Dry ice sublimates upon impact, leaving only the primary contaminant to dispose of. With Cold Jet dry ice cleaning machines, you eliminate water collection and treatment, chemical waste management, and spent media cleanup and disposal. The environmental benefits of dry ice blasting align with sustainability initiatives and reduce waste disposal costs.

-

Ensure Worker Safety and Compliance

Dry ice blasting eliminates the health and safety risks associated with manual cleaning methods. No more repetitive strain injuries from scraping and grinding or worker exposure to hazardous Volatile Organic Compounds (VOCs). Dry ice cleaning meets OSHA safety standards and creates a safer workspace.

-

Support Continuous Improvement Processes

By delivering fast, repeatable, and thorough cleaning, dry ice blasting supports key initiatives like 5S and Total Productive Maintenance (TPM). The consistency and speed of dry ice cleaning enables quick changeovers, shifting operation from costly, reactive repairs to a proactive preventive maintenance schedule.

Automotive Manufacturing Applications: What Can Dry Ice Blasting Clean?

Dry ice blasting provides significant operational benefits in the following cleaning applications in automotive facilities:

Clean Plastic and Rubber Molds In-Place with Dry Ice Cleaning

Cold Jet dry ice blasting machines enable automotive manufacturers and suppliers to clean all tooling hot and in-situ, dramatically reducing cleaning time and improving quality metrics across molding operations.

-

Significantly reduce mold cleaning time

Dry ice blasters thoroughly remove accumulated contaminants —including release agents, off-gas residue, and pigment deposits—from mold surfaces in a fraction of the time. Whether cleaning plastic injection molds for interior components, rubber molds for sealing systems, or poured polyurethane foam molds for seats, dry ice blasting cuts cleaning time by up to 75%. Dry ice cleaning excels across the full spectrum of automotive tooling, from precision LSR and LIM molds producing gaskets and connectors to compression molds forming critical automotive parts. Dry ice blasting quickly cleans injection molds in-situ (while hot and in the press), eliminating hours of cooldown and disassembly. Technical molds with complex cooling channels, urethane molds with intricate geometries, and extrusion dies with precise flow profiles are all cleaned effectively at operating temperature without disassembly.

-

Preserve mold integrity and eliminate defects

Non-abrasive dry ice cleaning safeguards all tooling without damaging surfaces or altering dimensions. With dry ice blasting, mirror-finish molds retain their polish, textured molds preserve A-surface finish, and rubber molds are maintained through thousands of cleaning cycles. Unlike abrasive methods that erode parting lines and critical features, dry ice cleaning preserves the original mold engineering while thoroughly removing contamination. Dry ice cleaning equipment enables more frequent preventive maintenance, eliminating the buildup that causes non-fills, flash, and dimensional variations.

-

No secondary waste, moisture, or contaminants

Dry ice sublimates completely upon contact, leaving zero residue, moisture, or chemicals on the mold surface or on the finished part. The pristine mold condition directly reduces scrap rates by preventing defects from contamination buildup, while the absence of secondary waste eliminates costly and time-consuming waste removal. Automotive suppliers report immediate quality improvements and faster changeovers between materials and colors with dry ice blasting.

-

Cleaning off-gas and mold release agent from plastic injection mold with dry ice cleaning

-

Dry ice cleaning removing off-gas and adhesive from rubber mold

Quickly Clean Weld Lines with Non-Abrasive Dry Ice Cleaning

In automotive assembly facilities, dry ice cleaning removes slag and spatter from fixtures and robots in weld cells without damaging clamps and proximity switches or requiring disassembly.

-

Significantly reduce cleaning time

Manual cleaning of welding jigs, shuttle jigs, and transfer cases takes hours and risks damaging expensive equipment. Dry ice blasting removes all welding residues—including slag, spatter, and smoke deposits—from weld tables, risers, and trunnions in minutes. Weld tooling and jigs that required 2–3 hours of manual cleaning are cleaned in 10–15 minutes with Cold Jet dry ice cleaning machines. Dry ice blasting cleans robotic welding cells, fixtures, and tooling without disassembly. Facilities report cleaning welding robots in minutes versus hours with dry ice blasting.

-

Prevent misalignment and sensor failures

Accumulation of weld spatter on tooling, robot axes, and proximity switches causes part misalignment, sensor malfunctions, and quality defects. The non-abrasive dry ice blasting process safely cleans around proximity switches and delicate robot components at welding stations, ensuring consistent weld quality and preventing the production interruptions that lead to lost output. The speed of dry ice cleaning enables maintenance of welding lines and stations between shifts rather than weekend shutdowns, maintaining optimal welding conditions continuously. With dry ice cleaning, automotive suppliers significantly reduce welding-related defects by cleaning fixtures and robot joints more frequently.

-

Extend weld fixture and tooling life

Dry ice cleaning eliminates the wear and damage caused by grinding, hammering, and chemical treatments on tooling and transfer tooling. Dry ice blasting preserves components of welding lines and extends service life by 2–3x. By protecting components, such as proximity switches and robot joints, from abrasive damage, facilities reduce replacement costs and unplanned downtime. Many automotive manufacturers report that reduced fixture replacement costs alone justify the dry ice cleaning investment within the first year.

-

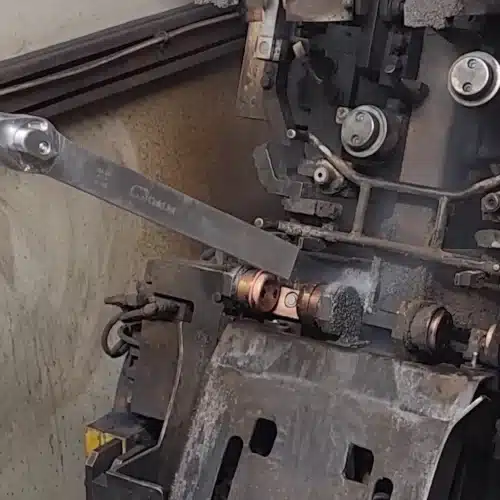

Cleaning robotic weld cell with dry ice blasting

-

Removing weld slag and spatter from fixtures in robotic weld cell

Dry Ice Blasting Cleans Paint and Coating Booths Without Water, Chemicals, or Disassembly

Dry ice blasting enables efficient cleaning of paint booths, E-coat systems, and the entire coating line without disassembling equipment or creating secondary waste.

-

Clean in-place without disassembly

Paint overspray accumulates on booth fixtures and walls, paint hooks and carriers, conveyors, and guide rails. Traditional cleaning requires equipment disassembly, the application of harsh chemicals, and high-pressure water. Cold Jet dry ice blasters clean all paint and coating components in-place, including E-coat lines, conveyors, and even booth flooring and downdraft grating. Dry ice cleaning eliminates moisture concerns in paint environments while removing layers of accumulated overspray from booth surfaces without damaging underlying equipment.

-

Reduce coating defects and rework

Cleaning with dry ice blasting allows for superior finishes across the entire finishing system. Dry ice cleaning machines remove paint overspray from fixtures, preventing flakes from contaminating wet paint downstream. Clean paint hooks and carriers ensure proper grounding for electrostatic systems, while properly maintained paint shop rollers enable smooth part movement. The thorough cleaning of spray booths eliminates the contamination that causes orange peel, fisheyes, and other coating defects. Facilities significantly reduce paint-related warranty claims after implementing dry ice cleaning of their paint booth fixtures.

-

Eliminate water and hazardous waste disposal

Traditional cleaning of paint lines and E-coat lines generates thousands of gallons of contaminated water and solvent waste. Dry ice sublimates completely, leaving only discarded paint chips to collect and dispose of properly. Dry ice cleaning reduces water treatment costs and hazardous waste volumes and simplifies environmental compliance. Dry ice blasting is a sustainable process that aligns with environmental initiatives.

-

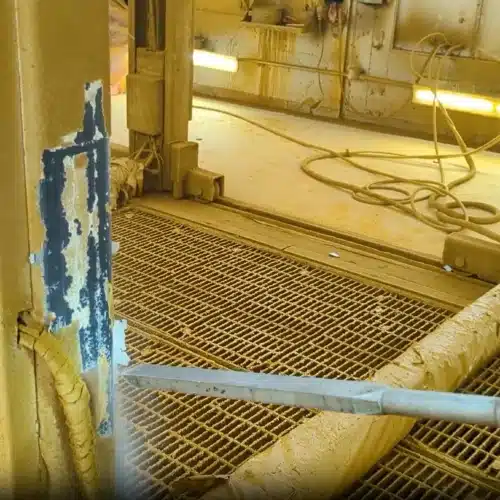

Dry ice blasting cleaning fixtures in paint booth

-

Dry ice cleaning removing paint from booth flooring and downdraft grating

Optimize Die Casting and Foundry Operations with Dry Ice Blasting

Non-abrasive dry ice blasting safely cleans permanent mold tooling, core boxes, and high-pressure die castings, eliminating costly production delays.

-

Accelerate maintenance cycles and reduce costs

Dry ice blasting machines enable more frequent cleaning of permanent aluminum molds, die cast tooling, and core boxes. This prevents the buildup of resins, die lube, release agents, and refractory coating that causes extended shutdowns. The ability to clean high-pressure die castings (HPDC) and semi-solid tooling in-line eliminates the costly cool-down and thermal cycling (reheat cycles), saving additional hours. Core boxes and shell core molds that required hours of manual cleaning are restored in 20–30 minutes with dry ice blasting. Facilities report annual savings exceeding $60,000 from reduced die casting cleaning time with Cold Jet dry ice blasting machines.

-

Clean dies, molds, and core boxes with zero tool wear or damage

Traditional manual cleaning, abrasive blasting, and cleaning with harsh chemicals cause tool wear and damage to critical surfaces. Non-abrasive dry ice cleaning eliminates expensive tool wear. Cold Jet dry ice blasting removes all contaminants, including vent blockage in core boxes and refractory coating from permanent molds, preserving surface finishes and dimensional accuracy. Traditional abrasive blasting destroys vents in core boxes, while dry ice blasting cleans vents without damage, saving facilities significant replacements costs. In addition, dry ice cleaning removes spent refractory coatings from HPDC, thixomolding, and all metal forming tooling without damage.

-

Prevent hazards and quality issues

Contamination buildup on core boxes, permanent molds, and HPDC causes part defects, sticking, and overall quality issues, leading to increased scrap rates. Regular dry ice cleaning removes all contaminants, while improving casting quality and consistency across foundry operations. Additionally, in die casting, accumulated die lube can ignite, causing equipment damage and safety hazards.

-

Removing buildup from die casting fixture with dry ice blasting

-

Dry ice blasting removing resins and chemicals from core box

Pre-Treatment with Dry Ice Blasting for Optimal Adhesion and Class A Finish

Cold Jet dry ice blasting provides superior pre-treatment for interior and exterior automotive components. Dry ice cleaning prepares plastic substrates for painting without moisture or residue.

-

Immediate coating application

Traditional surface preparation of plastic automotive parts with solvents and water requires extensive drying time before coating. Dry ice blasting removes oils and mold release agents from both interior and exterior automotive parts while leaving surfaces completely dry. With dry ice blasting, parts can move directly from the cleaning station to sealant application or painting. Dry ice cleaning machines eliminate flash-off ovens when preparing plastic substrates, reduce cycle times, and prevent moisture-related coating or film failures on critical automotive components.

-

Superior contaminant removal

Dry ice blasting ensures optimal paint adhesion by removing all surface contamination from automotive parts. Dry ice blasting removes process oils, release agents, handling residue, and light oxidation that cause coating or film failures. The complete removal of contaminants ensures proper adhesion when cleaning surfaces before sealant or paint application. Automotive suppliers experience a reduction in paint-related warranty claims after implementing dry ice blasting for pre-treatment.

-

Protect surface finish of parts

Unlike abrasive blasting that can alter surface profiles, dry ice cleaning removes contamination without affecting the substrate. Part dimensions, surface profiles, and design features remain unchanged, which ensures consistent film build and appearance across production runs. The gentle cleaning makes it safe for plastic components, maintaining the precise surface qualities required for Class A finish.

-

Pre-treatment of automotive bumper with dry ice cleaning

-

Surface preparation prior to painting with dry ice blasting

Dry Ice Blasting for Precision Deburring and Deflashing Without Part Damage

Cold Jet dry ice blasting provides controlled, non-abrasive removal of burrs and flash from molded automotive components and machined parts.

-

Preserve critical tolerances and part integrity

Dry ice blasting is non-abrasive and doesn’t alter critical automotive part geometries. The process removes burrs and flash without affecting dimensions, surface finishes, or intricate details on molded components. With dry ice cleaning, complex geometries found in automotive connectors, interior trim pieces, and delicate details on sensor housings remain unchanged. Dry ice blasters ensure automotive parts consistently meet critical tolerances, preventing costly scrap and maintaining the precise fit required for proper assembly and function.

-

No residual media or entrapment

Unlike abrasive blasting that can leave media embedded in parts, dry ice sublimates upon impact. As a result, no residual media or secondary waste is left behind. The risk of media entrapment is eliminated in critical areas like fastener threads or delicate holes in components. Automotive parts emerge clean and ready for assembly, eliminating secondary cleaning steps.

-

Precise and targeted deburring and deflashing

Dry ice blasting machines enable targeted removal of burrs and flash from specific areas without affecting surrounding surfaces or removing base material. Dry ice cleaning accesses hard-to-reach areas like internal channels, small holes, and complex geometries. This selective removal is essential for high-value automotive components where maintaining designed features and surfaces is critical for aesthetics and functionality.

-

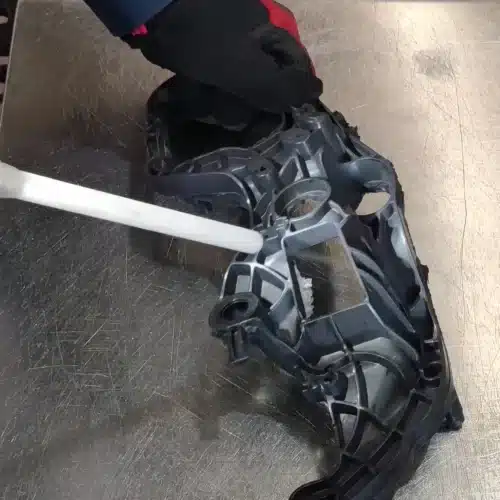

Deflashing molded automotive plastic part with dry ice blasting

-

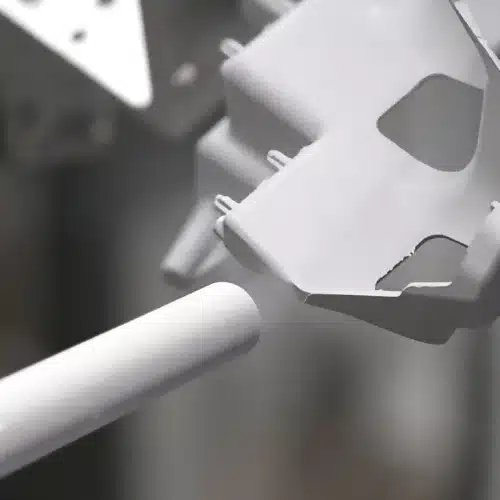

Automated deflashing of plastic automotive part with dry ice blasting

Cleaning Production Support Equipment and Facilities with Dry Ice Blasting

Cold Jet dry ice blasting enables comprehensive cleaning of automotive plant infrastructure and support equipment without disassembly, water, or line interruption.

-

Comprehensive facility and equipment cleaning

Dry ice blasting improves cleaning of production equipment, material handling systems, and critical plant infrastructure. Dry ice cleaning removes process buildup (grease, oil, dirt) and carbon residue from forklifts, CNC and machining equipment, and dyno equipment without disassembly or production shutdown. Dry ice blasting machines effectively clean equipment that was previously impossible or impractical to maintain, such as overhead cranes, ventilation systems, and tight spaces around production lines. Facilities using dry ice blasting for facility cleaning report extended equipment life, reduced unplanned downtime, and support for continuous improvement initiatives through cleaner, more efficient operations.

-

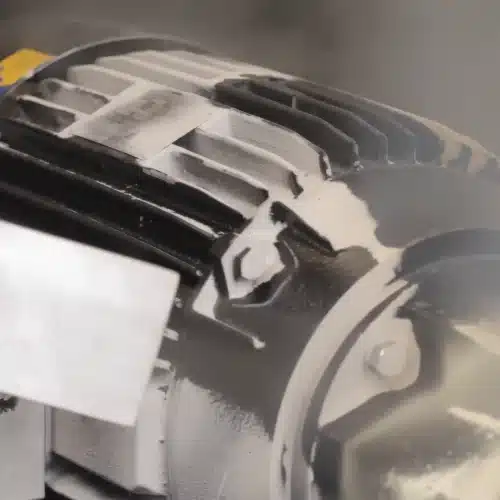

Safe cleaning for sensitive electrical components

Dry ice blasting removes years of accumulated grease, oil, and contamination from motors, PLCs/control cabinets, and cooling fans. The dry, non-conductive process is safe for electrical components. Dry ice blasting cleans electric motors without the need for powering down or masking. Electric motors, control panels, and conveyance systems that are regularly kept clean draw less amperage, resulting in lower energy costs.

-

Eliminate secondary waste and support sustainability initiatives

Unlike pressure washing that generates contaminated effluent, dry ice cleaning leaves only the removed contaminant to be swept up. Dry ice blasting eliminates water treatment requirements when cleaning in manufacturing environments, reduces hazardous waste disposal, and prevents the hours of cleanup required after traditional cleaning methods. Dry ice blasting machines use recycled CO2 that would otherwise be released into the atmosphere, supporting automotive manufacturers’ sustainability goals.

-

Dry ice blasting cleaning an electric motor in automotive plant

-

Dry ice blasting cleaning electric control panel

What is Required to Implement Dry Ice Cleaning?

Implementing an effective dry ice blasting program in your automotive facility requires several essential components:

-

Dry Ice Blasting Machine

Success begins with selecting the right dry ice cleaning system for your applications. Cold Jet offers a complete range of machines, from precision cleaning units for delicate molds to high-output systems for large-scale operations. Cold Jet’s patented Particle Control System (PCS®) technology allows real-time adjustment of cleaning parameters, enabling both gentle precision cleaning and aggressive contamination removal with a single machine. Each system includes all necessary hoses, applicators, and application-specific nozzles.

-

Compressed Air Supply

Automotive facilities will have existing compressed air systems that provide adequate supply. Cold Jet’s dry ice blasting machines typically operate at 100 cfm (2.8 m³/min) at 80 psi (5.5 bar). Cold Jet systems are engineered for efficiency, using less compressed air than competitive units while delivering superior cleaning performance.

-

Dry Ice Supply

Consistent access to high-quality dry ice ensures uninterrupted operations. Consumption varies by application, from 50 lbs/hour for precision mold cleaning to up to 200 lbs/hour for heavy contamination removal. We will help identify local suppliers and establish delivery schedules aligned with your production needs.

-

Operator Training and Certification

Proper training maximizes cleaning effectiveness and ensures safe operation. Cold Jet provides comprehensive training covering equipment operation, cleaning techniques, safety procedures, and maintenance. Our in-field specialists share best practices developed from thousands of successful implementations, helping your team achieve optimal results immediately.

-

Personal Protective Equipment (PPE)

Standard safety equipment includes insulated gloves, safety glasses, and hearing protection.

-

Automated Cleaning Systems (Optional)

Many automotive applications benefit from automation. Cold Jet dry ice blasting machines integrate seamlessly with robotic systems for consistent, repeatable cleaning. Automated solutions combine dry ice production, dry ice blasting equipment, and robotic controls for operation in injection molding, deflashing, and surface preparation applications.

What is the Best Dry Ice Blasting Machine for Automotive Manufacturing?

Cold Jet offers proven dry ice blasting solutions specifically engineered for the demanding requirements of automotive manufacturing facilities.

-

Aero2 PCS ULTRA

The Aero2 PCS ULTRA delivers unmatched versatility for automotive facilities, from gentle precision mold cleaning with MicroParticle dry ice to aggressive contamination removal with 3mm dry ice granules. Cold Jet’s patented Particle Control System enables real-time parameter adjustment, making it the ideal single-machine solution for facilities with diverse cleaning requirements. The Aero2 PCS ULTRA is designed for easy automation integration.

Aero2 PCS® ULTRA -

Aero2 PLT ULTRA

The Aero2 PLT ULTRA provides maximum power for automotive manufacturing's toughest cleaning challenges. This innovative dry ice blaster excels at large-scale operations and heavy equipment maintenance where continuous, powerful blasting is critical for productivity.

Aero2 PLT® ULTRA -

Aero 40FP

Built for demanding production environments, the Aero 40FP combines proven durability with consistent performance. This workhorse machine features pulse-free blasting technology, ideal for high-volume cleaning operations requiring dependable, repeatable results.

Aero® 40FP

Why Invest in Cold Jet Dry Ice Cleaning for Automotive Manufacturing?

When selecting dry ice cleaning equipment for your automotive facility, Cold Jet delivers measurable advantages that directly impact your bottom line. Cold Jet machines consistently provide a faster ROI and a lower total cost of ownership than any alternative.

-

Automotive Industry Leadership

With more than three decades of experience and thousands of automotive installations worldwide, Cold Jet understands the unique challenges of automotive manufacturing. From Tier 1 injection molders to OEM assembly plants, we have developed proven solutions for every automotive application. Our expertise translates directly to faster implementation and superior results in your facility.

-

Trusted by Global Automotive Leaders

The world’s leading automotive manufacturers rely on Cold Jet, with over 24,000 systems installed globally. Major OEMs and suppliers trust Cold Jet dry ice blasting for their critical cleaning applications. This extensive installed base provides proven reliability and continuous innovation based on real-world automotive experience.

-

Superior Reliability and Longevity

Cold Jet dry ice cleaning machines are engineered for 24/7 production environments. Our systems demonstrate a significantly longer service life than competitive units. The robust construction and quality components minimize unplanned downtime, ensuring consistent production support. Extended warranties and comprehensive service programs protect your dry ice blaster investment.

-

Lower Operating Costs

Cold Jet dry ice cleaning systems consume less dry ice than competitive machines while delivering superior cleaning results. Cold Jet’s efficient designs also use less compressed air and electricity, reducing utility costs. The combination of lower consumable usage and minimal maintenance requirements provides the lowest cost per cleaning in the industry. Many automotive facilities achieve complete ROI within 6–18 months.

-

Comprehensive Technical Support

Cold Jet’s technical experts provide unmatched support from initial evaluation through ongoing optimization. Regional service technicians understand automotive production requirements and respond quickly to maintain maximum uptime. Comprehensive training programs ensure your team maximizes cleaning effectiveness.

-

Application Specific Accessories

Cold Jet’s application-specific nozzles, specialized applicators, and durable blast hoses address the unique requirements of automotive manufacturing. From high-flow nozzles for weld line cleaning to precision nozzles for sensor cleaning, we provide the complete solution for every application.

OUR CUSTOMERS & WHAT THEY SAY ABOUT US

Automotive manufacturers worldwide achieve measurable results with Cold Jet

With proven success at over 24,000 installations globally, Cold Jet delivers tangible value to automotive manufacturers of every size.

Frequently Asked Questions

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.