By cleaning in place, we have addressed the operator safety issues associated with pulling a hot mold. One of the most notable gains is the increased productivity by cleaning our molds in-place, thus extending our production runs. We now use dry ice blasting in all of our manufacturing facilities.

Dry ice cleaning equipment for Rubber & Tire Molds

Keep your tire and rubber mold presses running

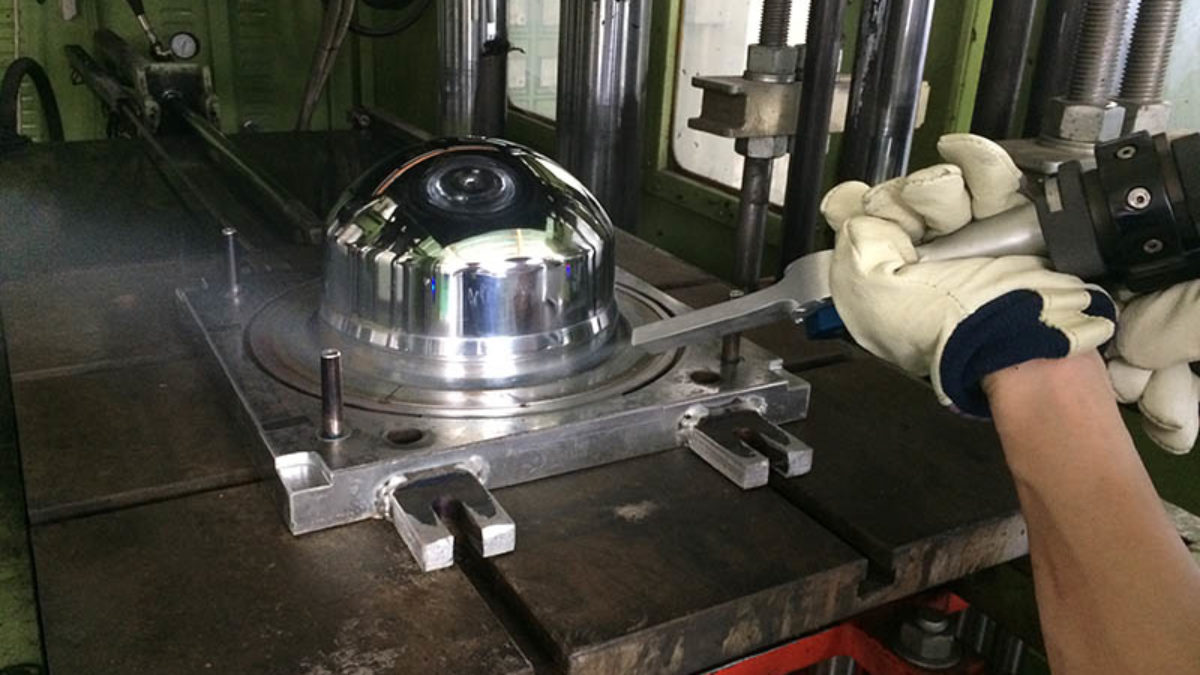

Buildup of cured material and mold release agents causes sticking molds, blemishes and unwanted flash on final parts, making them unusable and requiring press shutdown for cleaning. Traditional cleaning methods can be time consuming, ineffective, damaging to molds and result in high labor and material costs. Turn to rubber & tire mold dry ice cleaning equipment for a faster, more efficient, and gentler solution.

Dry ice blasting is an in-place, online or offline, quick and effective way to clean without damaging expensive molds.

Rubber Mold Cleaning

Improve product quality while reducing production downtime

Benefits

Dry ice blasting safely cleans rubber molds while hot and online, reducing downtime and eliminating mold fouling.

- Eliminate complete shutdowns

- Clean in-place No mold disassembly

- Improve product quality and reduce scrap

- Non-abrasive No impact damage or mold erosion

- Increase production time

- Reduce cleaning time and labor costs

- Environmentally sustainabilityNo secondary waste

Specific use cases:

- Injection molds

- Blow molds

- Compression molds

- Silicone rubber injection molds

- Metal bonded molds

- Lift presses

- Tilt back presses

- +More

Tire Mold Cleaning

Reduce production downtime by effectively cleaning tire molds online

Benefits

Dry ice cleaning extends running times and reduces defects and scrap rates by cleaning tire molds in-press without damaging spring vents.

- Reduce production downtime

- Decrease scrap rates and defects

- Non-abrasive No impact damage

- No tire mold disassembly

- Labor cost reduction of up to 75% when cleaning online

- No secondary waste

- Environmentally sustainability

Specific use cases:

- Steel tire molds

- Aluminum tire molds

- Coated tire molds

- Segmented tire molds

- Two piece tire molds

- Spring vented tire molds

- Tire molds with complex surface patterns

- Lift presses

- Tilt back presses

- +More

Benefits of Dry Ice Blasting

Eliminate mold fouling and production downtime by safely cleaning molds online

Dry ice blasting allows rubber and tire molders to clean their molds in-press, at operating temperatures. Cleaning molds online eliminates complete shutdowns, reduces production downtime and improves product quality.

- Eliminate complete shutdowns and reduce downtime

- Clean hot and online No mold disassembly or cooldown required

- Reduce scrap rates and eliminate reassembly damage

- Non-abrasive Will not damage or erode molds

- Reduce cleaning time and labor costs

- No secondary waste stream

- Environmentally sustainableNo secondary waste

- Operationally safe Eliminates manual cleaning and exposure to unsafe conditions

Case Studies

Proven technology produces definable results

Our solutions are driving real results in our customers’ organizations.

Rubber & Tires Dry Ice Cleaning Technology

Dry Ice Cleaning for Rubber

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.