With dry ice cleaning, the quality of our finished parts increased greatly. Power washing leads to varnishing and stains on the parts, while dry ice cleaning eliminates this.

Dry Ice Cleaning: Maximizing Production and Precision for Plastics Manufacturing

The plastics industry encounters complex cleaning challenges that impact efficiency, product quality, and profitability. Traditional cleaning methods are often abrasive, time-consuming, require significant downtime, increase scrap rates, and lead to lost production. These challenges directly affect the profitability of plastics processors.

Dry ice cleaning addresses the pain points of plastics manufacturing industry cleaning. It is a non-abrasive cleaning process for plastic molds that enables molds to be cleaned in-place at operating temperature. Dry ice blasting also allows for targeted and precise parts finishing and is a non-aqueous solution for surface preparation.

Ready to optimize your plastics production? Reach out to us today to explore how our dry ice cleaning equipment for plastics manufacturing industry cleaning can improve your processes.

What are the Benefits of Dry Ice Cleaning in the Plastics Industry?

Dry ice cleaning machines improve productivity, enhance part quality, and prolong equipment life

Dry ice blasting consistently improves plastic processors’ production efficiencies. Whether you are cleaning molds, deburring or deflashing parts, or preparing plastic surfaces for paint, dry ice blasting machines will enable you to act faster and more effectively. The process improves product quality and consistency, while significantly reducing scrap rates and rejected parts. Because dry ice sublimates on contact, it leaves no residual media, chemicals, or secondary waste, ensuring a clean and pristine plastic component.

-

Maximize Manufacturing Efficiency

Dry ice cleaning machines boost operational efficiency in plastics manufacturing industry cleaning. Dry ice quickly cleans molds in-place, instantly removes burrs and flash from finished parts, and enables immediate painting or coating without the need for drying. By eliminating the need for time-consuming manual processes, dry ice cleaning boosts productivity, decreases downtime, and increases output.

-

Non-Abrasive Cleaning Process

Dry ice cleaning is a non-abrasive process that will prolong the service life of your equipment and maintain the integrity of finished products. The plastic cleaning process will not affect mold dimensions or mold details. Dry ice blasters will also preserve the geometries and surfaces of finished parts.

-

Improved Part Quality

Dry ice blasting equipment helps plastics manufacturers meet contract specifications and improve part quality. The plastics manufacturing industry cleaning process enables plastic molds to be cleaned in-place in a fraction of the time, which allows them to be cleaned more frequently. Clean molds result in high-quality parts and reduced scrap rates.

-

No Secondary Waste

Dry ice sublimates and does not produce a secondary waste stream. The process eliminates the need for water, harmful chemicals, and other aqueous solutions. No water, chemicals, or secondary media will be left on the mold or finished part.

-

No Residue or Contaminants

Dry ice does not leave chemical residue or other contaminants on finished plastic parts or molds, which can lead to cross contamination and scrapped parts.

-

Non-toxic and Safe for Employees

Dry ice cleaning is an occupationally safe cleaning solution. Dry ice is non-toxic and safer for employees than traditional cleaning methods. The process eliminates tedious manual cleaning and eliminates exposure to chemicals.

What Can Dry Ice Blasting Clean in Plastics Manufacturing?

Dry ice blasting machines help plastics manufacturers reduce scrap and downtime, improve product quality, prolong the service life of their equipment, and increase profitability. It is an effective solution for a variety of applications in plastics manufacturing industry cleaning.

-

Plastic Mold Cleaning

-

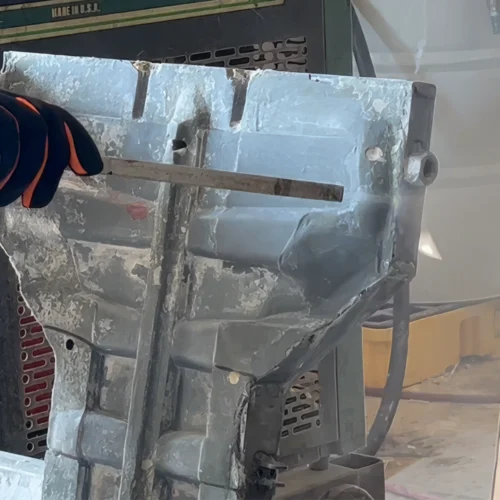

Deburring and Deflashing of Plastic Parts

-

Surface Preparation Prior to Painting or Coating

-

Composite Tool Cleaning

Clean Plastic Molds In-Place and Improve Part Quality with Dry Ice Cleaning

Dry ice blasting enables plastic manufacturers to clean molds while hot and online for increased production and part quality.

-

Faster and more effective

Dry ice blasting is a superior solution for cleaning plastic molds, whether in-press or offline. The process reduces cleaning time by up to 75%. Dry ice cleaning removes mold release agents, resin off-gases, and cured materials from all areas of the mold – even hard-to-access areas like cavities, crevices, and vents. When cleaning online, the mold can remain at operating temperature, which eliminates the need for cooldown, disassembly, and reassembly. The process enables you to boost production capacity, reduce rejection rates, and enhance overall product quality.

-

Protect mold integrity and improve part quality

Non-abrasive dry ice cleaning prevents mold wear, preserves finishes, and maintains critical tolerances, which prolongs the service life of the mold and leads to higher-quality parts. The ability to clean in-place and in a fraction of the time results in more frequent cleaning. Cleaner molds lead to consistently high-quality parts, drastically cutting down on scrap and rejections.

-

No waste or residue

Dry ice sublimates back to a gas when it hits the surface of the mold. The cleaning process will not leave residue, chemicals, or moisture on the mold or the finished product. Dry ice cleaning also eliminates the need for chemical cleaning solutions or water. This results in fewer scrapped parts and prevents cross-contamination issues.

-

Cleaning injection mold with dry ice cleaning machine

-

Cleaning off gassing from plastic mold with dry ice blasting

-

Removing residual plastic and pigment from plastic mold with dry ice blasting

Dry Ice Cleaning Quickly and Safely Deburrs and Deflashes Plastic Parts

Dry ice blasting is a non-abrasive and precise parts finishing solution for machined and molded plastic parts.

-

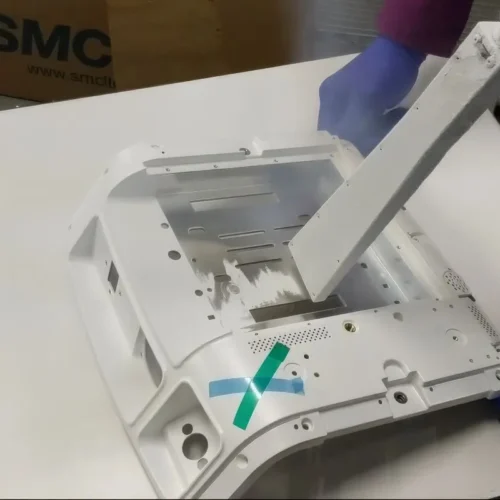

Non-abrasive process protects parts

Dry ice blasting is a non-abrasive process that removes burrs and flash without damaging delicate part surfaces, dimensions, critical features, or tight tolerances. This ensures that the aesthetic and functional integrity of your plastic components remains intact. Unlike traditional methods that can lead to surface degradation or dimensional changes, dry ice blasting maintains the original design and specifications of each part, resulting in consistently high-quality products.

-

Precise process with no residual media

Dry ice cleaning consistently produces uniform finishes by precisely targeting problem areas and ensuring only unwanted material is removed. Dry ice sublimates back to gas, which eliminates issues like grit entrapment and cross-contamination. Dry ice blasting minimizes scrap rates and rejections, allowing you to consistently deliver flawless components that meet the most stringent quality requirements.

-

Faster and more effective process

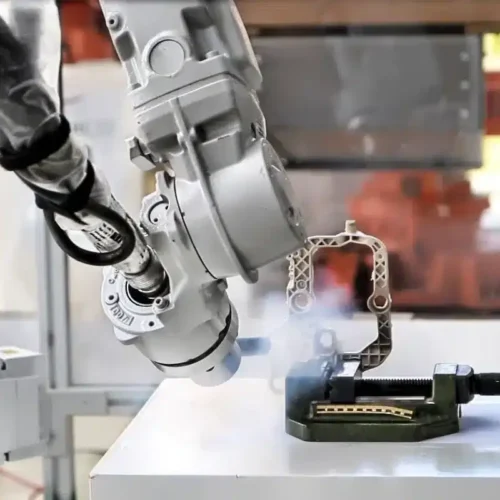

Dry ice blasting reduces parts finishing time by eliminating slow, labor-intensive manual methods and the need for post-process cleaning. Its precise targeting capabilities mean that excess material is removed swiftly and accurately, even from complex geometries and hard-to-reach areas. By integrating seamlessly into automated systems, dry ice blasting streamlines your operations, helping you achieve higher throughput and faster turnaround times.

-

Automated deburring of plastic part with dry ice blasting equipment

-

Removing flash and burrs from plastic part with dry ice cleaning machine

-

Deburring machined plastic part with dry ice blasting

Non-Aqueous Surface Preparation with Dry Ice Cleaning

Dry ice blasting effectively removes all contaminants from plastics without water or abrasion.

-

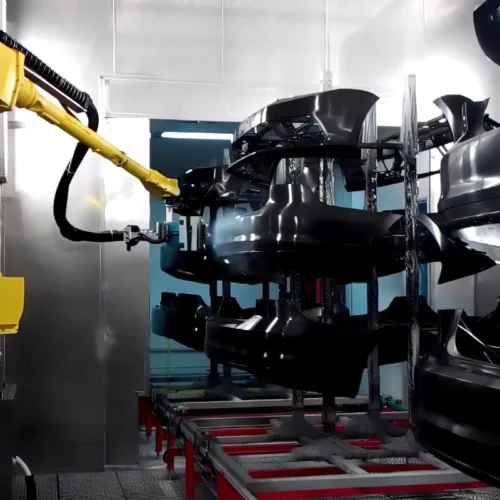

Superior contaminant removal

Dry ice blasting completely removes mold release agents, oils, dust, and other manufacturing contaminants that can jeopardize paint and coating adhesion. Dry ice sublimates, which eliminates issues like secondary media, moisture, or chemicals being left on the part. The process leads to a clean and activated surface, allowing paints and coatings to form a direct, robust bond with the substrate.

-

No water or drying time

Dry ice blasting is non-aqueous, which enables immediate paint-ready surfaces. Parts can move from cleaning to painting or coating, eliminating the need for drying ovens and water reclamation systems. By significantly reducing cycle times, dry ice blasting boosts your overall production efficiency and throughput.

-

Non-abrasive process

Protect your plastic components with non-abrasive dry ice blasting. This process removes contaminants without affecting the parts surface finish. By preserving surface texture and the geometry of the part, dry ice cleaning ensures consistent coating thickness and aesthetic quality crucial for high-quality products.

-

Cleaning automotive bumper prior to painting with automated dry ice blasting

-

Automated dry ice blaster cleaning automotive parts prior to painting

-

Coating surface preparation with dry ice blasting machine

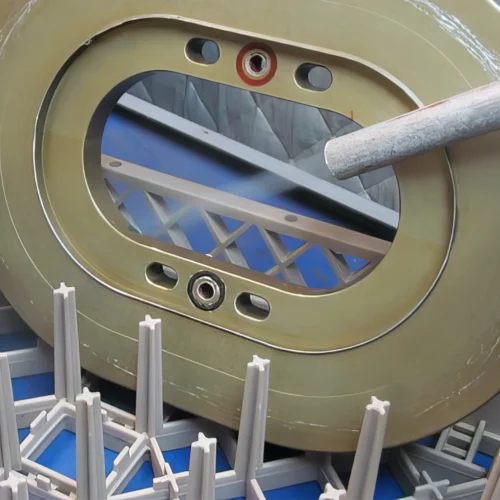

Safe and Efficient Composite Tool Cleaning with Dry Ice Blasting

Non-abrasive dry ice blasting effectively cleans tooling and extends their operational life.

-

Extend tool service life

Dry ice blasting is a non-abrasive cleaning method that safeguards critical tolerances, shutoffs, and intricate details. Unlike traditional methods that can wear away or damage delicate surfaces, dry ice cleaning preserves the original precision and integrity of tooling. Molds maintain their exact specifications, leading to consistent, high-quality parts, while significantly extending the service life of your tooling.

-

Boosted production efficiency

Dry ice cleaning enables you to clean molds in-line and at operating temperatures, eliminating the need for costly cooldown and reheating cycles. By avoiding disassembly and reassembly, you drastically reduce downtime and manual labor. This efficiency translates to more frequent cleaning, fewer rejected parts, and a notable increase in overall production output.

-

No waste or residue

Dry ice blasting thoroughly eliminates a wide array of residues, including stubborn release agents, resins, oils, and other production contaminants that can compromise part quality. Dry ice sublimates upon impact, leaving no secondary waste, abrasive media, or chemical residue. This ensures a clean mold surface, which prevents contamination risks and eliminates additional cleaning steps.

-

Dry ice blasting cleaning composite tooling

-

Dry ice blasting removing resin from composite mold

-

Removing gel coat buildup from composite mold with dry ice blasting

What Do Plastics Manufacturers Need for Dry Ice Cleaning?

An effective dry ice blasting setup at your facility relies on several key components:

-

Dry Ice Blasting Machine

A successful plastics manufacturing cleaning process begins with a reliable and easy to use dry ice cleaning system. Cold Jet provides a comprehensive line of dry ice blasters, including models with IoT and our patented Particle Control System (PCS®). This technology allows you to precisely fine-tune cleaning parameters and dry ice particle size, enabling both delicate and more aggressive cleaning. Each blaster arrives complete with blast and air hoses, an applicator, and a nozzle for your specific application.

-

Compressed Air

Your facility’s existing filtered air system can supply the necessary compressed air. Cold Jet dry ice cleaning systems typically require 100 cfm (2.8 m³/min) at 80 psi (5.5 bar).

-

Dry Ice Supply

A supply of high-quality dry ice is vital for uninterrupted cleaning operations. Average consumption is approximately 88 lbs. per hour, but can vary based on your application. We can help you identify a dry ice supplier. Once identified, establish a delivery schedule that aligns with your production schedules.

-

Machine and Operator Training

Proper training is essential for operators to effectively and safely utilize dry ice blasting for cleaning in the plastics industry. Cold Jet offers a comprehensive training course designed to equip your team with essential operating techniques for effective cleaning practices and safety guidelines.

-

Personal Protective Equipment (PPE)

Your cleaning personnel should always wear appropriate safety gear, including gloves, hearing protection, and eye protection.

-

Automated Cleaning System (Optional)

Dry ice blasting processes for plastics are often integrated into automated production lines. Fully automated dry ice cleaning solutions combine a dry ice maker, a dry ice blaster, and a robotic arm.

What Is the Best Dry Ice Blasting Machine for the Plastics Industry?

Cold Jet offers a comprehensive line of dry ice blasters for plastics manufacturing industry cleaning. Our user-friendly, durable, and mobile systems are ideal for plastics manufacturing facilities.

-

Aero2 PCS ULTRA

The Aero2 PCS ULTRA is a highly versatile machine for a broad spectrum of plastics manufacturing industry cleaning. The dry ice blaster is suited for applications requiring extremely gentle cleaning with MicroParticle dry ice to aggressive cleaning of larger surfaces using 3mm dry ice granules.

Aero2 PCS® ULTRA -

i3 MicroClean 2

The i3 MicroClean 2 represents the next generation in precision cleaning. This dry ice blasting machine features intuitive controls in a lightweight, compact design. You can easily adjust cleaning aggression to lock in the ideal parameters for your specific application.

i3 MicroClean® 2 -

i3 MicroClean

The i3 MicroClean is an efficient, lightweight machine that proves highly effective in a wide range of cleaning needs for the plastics industry.

i3 MicroClean®

Why Invest in Cold Jet Machines in the Plastics Industry?

When enhancing your cleaning and maintenance processes, investing in a Cold Jet dry ice blasting machine is a strategic investment that elevates your operation’s efficiency. As you evaluate this capital investment, consider both the return on investment (ROI) and the significant operational advantages unique to your plastic part manufacturing facility. Cold Jet machines consistently deliver faster ROI and greater value than competitors.

-

Plastics Industry Expertise

Leveraging extensive experience spanning decades in the plastics sector, Cold Jet has cultivated an in-depth knowledge of the critical cleaning challenges and operational demands faced by the plastics industry.

-

Trusted by the Plastics Industry

With more than 24,000 machines installed globally and installations in the leading plastics manufacturers’ facilities, Cold Jet is a trusted solution for plastics manufacturing industry cleaning.

-

Industry Leading Reliability

Our machines are built to meet the demands of high production environments. Cold Jet dry ice blasting machines are more reliable and have significantly longer machine life than competitors.

-

Lower Operating Costs

Cold Jet dry ice blasters are engineered for efficiency, consuming considerably less dry ice, compressed air, and electricity than other machines on the market. This translates directly into reduced daily operational expenses, all while upholding the highest standards of cleaning quality and safety.

-

Unmatched Support and Training

Our regional technicians have a deep understanding of the unique requirements within plastic part manufacturing environments and are always accessible. We provide both expert maintenance services and comprehensive equipment training to ensure your team’s success.

-

Application Specific Accessories

Our extensive selection of accessories, including various applicators, blast hoses, and application specific nozzles, help you configure the optimal setup for your unique operational needs.

OUR CUSTOMERS & WHAT THEY SAY ABOUT US

Plastics manufacturing customers around the world rely on Cold Jet

With a global installed base of 24,000+ that consists of companies large and small, Cold Jet delivers real value to plastics manufacturers.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.