Cold Jet’s equipment is bar none the best cleaning quality we can achieve. Coatings and deodorizers are used at a minimum because it eliminated 100% of the charred wood and carbon which houses the smell.

Remove Fire, Smoke, and Mold Damage Faster and More Effectively with Cold Jet Dry Ice Blasting

Cold Jet’s dry ice cleaning machines deliver superior remediation results for restoration contractors, mold remediation specialists, and disaster recovery professionals. By replacing labor-intensive sanding, moisture-adding chemical treatments, and waste-generating soda blasting with a quicker and completely dry solution, contractors achieve the following results with dry ice cleaning:

- Reduced Project Time & Labor: Dry ice blasting dramatically reduces remediation timelines by eliminating labor-intensive sanding and brushing, chemical and encapsulant application, secondary waste cleanup, and the multiple treatment passes required by traditional methods. Dry ice blasting enables contractors to complete projects with fewer people and in less time.

- Clean Hard to Reach Areas: Dry ice blasting cleans around boards and joists, around nails, and in the nooks and crannies that traditional methods cannot reach. This results in the removal of 100% of the contaminants, such as mold spores, smoke soot, and char.

- Zero Secondary Waste Stream: Dry ice sublimates on contact, eliminating the cleanup time that soda blasting requires (often 1.5x the blast time). Collection and disposal costs are also eliminated.

- Completely Dry Process: Unlike chemical treatments that reintroduce moisture to already-compromised structures, dry ice blasting leaves surfaces dry—critical for preventing future mold growth.

- Eliminate Odor at the Source: Dry ice cleaning removes odor-causing carbon deposits rather than masking them with sealants and deodorizers.

- ROI in 2-4 Projects: Equipment investment typically pays for itself within the first few jobs, with single commercial fire restoration projects generating up to $20,000 in labor savings.

Ready to increase your project capacity and profitability? Contact us today to learn how Cold Jet dry ice blasting machines can transform your restoration and remediation business.

What are the Benefits of Dry Ice Cleaning for Restoration & Remediation?

Dry ice blasting machines reduce project times, eliminate secondary waste, and deliver superior cleaning results

Cold Jet dry ice blasting consistently improves restoration contractors’ operational efficiency and project profitability. Whether you are remediating fire damage, removing mold from attics and crawl spaces, or restoring water-damaged structures, dry ice blasting machines enable you to work faster and achieve better results. The process completely removes contaminants and odor-causing residue, while eliminating biocide and encapsulant application and secondary waste cleanup that adds days to remediation projects.

Cold Jet dry ice blasting provides the following benefits for restoration and remediation projects:

-

Significantly Reduced Project Time and Labor

Dry ice blasting reduces remediation time by up to 70% compared to traditional methods. A 2,000 sq. ft. attic mold remediation project that requires 10 days and a crew of 10 workers using traditional sanding methods can be completed in 2 days with just 2 operators using dry ice blasting. By eliminating labor-intensive hand scraping, biocide and encapsulant application, and time-consuming secondary waste cleanup, contractors complete more projects per month and increase revenue capacity.

-

No Secondary Waste

Dry ice sublimates on impact and does not produce secondary waste streams. Unlike soda blasting, which requires cleanup time equal to 1.5x the blast time, dry ice cleaning eliminates the need for blasting media collection and disposal. This significantly reduces encapsulation costs, overall project duration, and the environmental risks associated with soda blasting.

-

Complete Contaminant Removal

Cold Jet dry ice blasting achieves 100% removal of smoke soot, char, and mold spores. The process removes odor-causing carbon deposits rather than masking them with chemicals or sealants. By completely removing mold spores, dry ice cleaning eliminates the risk of mold regrowth.

-

Eliminate Biocide and Sealant Application

Traditional mold remediation methods cannot achieve complete spore removal, requiring follow-up biocide applications to kill remaining mold and sealants to encapsulate residual staining. Dry ice blasting removes 100% of mold spores and staining in a single pass, eliminating the need for chemical biocide treatments and reducing or eliminating encapsulant requirements. This saves material costs and shortens project timelines.

-

Safe for Operators and Environments

Dry ice is non-toxic, non-corrosive, and non-conductive. The process eliminates exposure to harsh chemicals and can be used safely around electrical wiring and components. Operators experience less physical strain compared to hand sanding and brushing, while neighboring businesses or households are not affected by chemical fumes or abrasive debris.

Key Restoration & Remediation Applications for Dry Ice Blasting

Cold Jet dry ice blasting machines help restoration contractors reduce project time by up to 70%, increase profit per project, and deliver superior results. Dry ice cleaning is an effective solution for a variety of restoration and remediation applications.

-

Fire and Smoke Remediation

-

Mold Remediation

Remove Fire and Smoke Damage Faster and More Effectively with Dry Ice Blasting

Dry ice blasting enables restoration contractors to clean fire-damaged structures in a fraction of the time while achieving complete removal of char, soot, and odor-causing residue.

-

Faster Cleaning Process

Dry ice blasting cleans fire-damaged surfaces at rates as fast as 10 sq. ft. per minute—significantly faster than hand wiping and sanding. The process eliminates the secondary cleanup time required by traditional methods, which often takes days. By comparison, soda blasting requires debris collection and disposal that often takes 1.5x the blast time. Dry ice sublimates on contact, leaving only the removed contaminant to manage.

-

Reduce Labor Costs

Fire restoration projects can reduce labor requirements by 50-70% with dry ice blasting while significantly compressing project timelines. The labor savings translate directly to increased profitability per project. Contractors can achieve ROI on their dry ice blasting equipment in as few as 2-4 fire restoration projects, with single jobs generating up to $20,000 in labor savings on commercial projects. Additionally, dry ice blasting is less physically demanding than hand wiping and sanding, and the cooling effect of dry ice provides relief for operators working in hot environments like attics and crawl spaces.

-

Eliminate Odor without Replacing Roof

Traditional fire remediation relies on coatings and deodorizers to mask the smell of smoke damage. These treatments cover but do not eliminate the odor-causing carbon deposits embedded in wood grain and porous surfaces. Oftentimes, insurance providers require the replacement of the smoke-damaged roof. Dry ice blasting removes 100% of the charred material and carbon residue, eliminating the need for roof replacement.

-

Removing soot from a metal ceiling with dry ice cleaning

-

Dry ice blasting removing smoke and soot from fire-damaged wood

-

Removing fire damage and soot from hardwood floors with dry ice cleaning

Achieve Complete Mold Removal with Dry Ice Blasting

Dry ice blasting removes 100% of mold spores from wood surfaces in significantly less time, often eliminating biocide and encapsulation steps.

-

Complete Removal of Mold Spores

Traditional mold remediation methods—sanding and wire brushing—cannot access hard to reach areas, such as between boards and joists, around wiring and HVAC components, and around nails. These methods cannot fully remove mold spores, requiring biocide and encapsulant after cleaning. Cold Jet dry ice blasting achieves complete mold spore removal, which eliminates the need for biocide and encapsulant application. Documented users of dry ice blasting for mold remediation consistently pass Post Remediation Verification (PRV) clearance tests.

-

Dramatically Reduce Project Time and Labor

Eliminating biocide and encapsulant application significantly reduces overall project time. A 2,500 sq. ft. mold remediation project drops from 500 labor hours to 50 hours with dry ice blasting. Typical mold remediation projects require up to 10 workers with traditional methods, while dry ice blasting typically requires only 2 operators.

-

Clean in Confined Spaces Safely and Thoroughly

Attics, crawl spaces, and areas behind walls present significant challenges for mold remediation. Traditional methods require workers to sand or apply chemicals in awkward positions in environments that are often extremely hot. Cold Jet dry ice blasting is more ergonomic, and the cooling effect of dry ice provides welcome relief for operators working in these confined, high-temperature spaces.

-

Dry ice blasting removing mold spores resulting from water damage

-

Basement mold remediation with dry ice cleaning

-

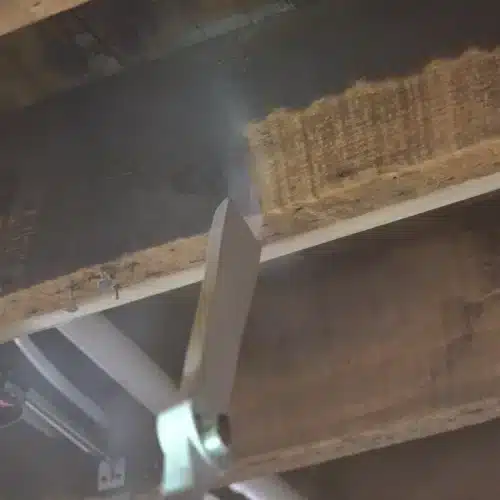

Removing mold from wood beams with dry ice blasting

What Do Restoration Contractors Need for Dry Ice Blasting?

An effective dry ice blasting operation for remediation and restoration relies on several key components:

-

Dry Ice Blasting Machine

A successful restoration operation begins with a reliable and portable dry ice blasting system. Cold Jet provides a comprehensive line of dry ice blasters designed for the demanding conditions of remediation job sites. Systems range from entry-level machines for contractors adding dry ice blasting to their services to blasters for large-scale commercial fire restoration projects. Each system includes blast and air hoses, applicator, and application-specific nozzles.

-

Compressed Air

Dry ice blasting requires a supply of clean, dry compressed air. Many contractors use portable diesel air compressors that can be positioned outside the structure being cleaned. Air treatment ensures dry ice flows consistently without clumping.

-

After Cooler

An after cooler may be useful if you are using a portable diesel compressor as your air source. An after cooler removes most of the moisture from the system and cools the air to temperatures needed for trouble-free cleaning.

-

Dry Ice Supply

A reliable supply of 3mm dry ice pellets is essential for uninterrupted remediation work. Cold Jet can connect you with dry ice suppliers in your region.

-

Operator Training

Proper training ensures operators achieve optimal cleaning results while following safety protocols. Cold Jet provides comprehensive training covering equipment operation, effective cleaning techniques, and safety procedures for remediation projects.

-

Personal Protective Equipment (PPE)

Remediation work requires appropriate safety gear including hearing protection, safety glasses, and work gloves.

What Is the Best Dry Ice Blasting Machine for Restoration & Remediation?

Cold Jet offers a comprehensive line of dry ice blasters for restoration and remediation applications. Our durable and portable systems are designed for the demanding conditions of remediation work sites. All Cold Jet dry ice blasters are effective for remediation work, with options ranging from entry-level systems to high-performance machines. Some of the most popular choices for remediation projects include:

-

Aero2 PCS ULTRA

The Aero2 PCS ULTRA features Cold Jet's patented Particle Control System® technology, enabling precise adjustment of dry ice particle size from aggressive cleaning to extremely gentle treatment. This versatility is essential for restoration contractors who encounter everything from heavy char on structural timber to delicate cleaning of soft woods and historic surfaces. The PCS ULTRA adapts to the full range of remediation applications with a single machine.

Aero2 PCS® ULTRA -

Aero2 PLT ULTRA

The Aero2 PLT ULTRA is a high-performance pellet blaster ideal for fire restoration and large-scale remediation projects. Its robust output enables fast cleaning rates on commercial structures while maintaining the portability required for restoration job sites. The PLT ULTRA delivers consistent performance across extended blasting sessions typical of fire damage cleanup.

Aero2 PLT® ULTRA -

Aero 40FP

The Aero 40FP is a proven workhorse for mold remediation and residential fire restoration. Its reliable performance and straightforward operation make it ideal for contractors entering the dry ice blasting market. The 40FP delivers consistent cleaning results across a range of remediation applications and offers a cost-effective entry point for restoration businesses looking to add dry ice blasting to their service capabilities.

Aero® 40FP

Why Invest in Cold Jet Machines for Restoration & Remediation?

Investing in dry ice blasting equipment is a strategic decision that can transform your restoration business. Cold Jet machines consistently deliver faster ROI and greater operational value than competitors. Consider both the return on investment and the significant competitive advantages dry ice blasting provides.

-

Restoration Industry Expertise

Cold Jet has worked with restoration and remediation contractors for decades, developing deep knowledge of the specific cleaning challenges and operational demands of fire, smoke, mold, and water damage restoration.

-

Proven ROI

Restoration contractors typically achieve ROI on their dry ice blasting investment within 2-4 projects. A single fire restoration project can generate $10,000-$20,000 in labor savings compared to traditional methods. Mold remediation contractors report equipment payback in less than 4 jobs based on significant labor cost reductions.

-

Trusted by Leading Restoration Companies

With more than 24,000 machines installed globally, Cold Jet is the trusted choice for restoration professionals. Companies ranging from national franchise networks to independent contractors rely on Cold Jet equipment for fire restoration, mold remediation, and specialty restoration applications.

-

Industry-Leading Reliability

Our machines are built to withstand the demanding conditions of remediation job sites. Cold Jet dry ice blasting equipment is more reliable, more durable, and has significantly longer service life than competing machines. This reliability is critical for contractors who depend on equipment availability to meet project deadlines.

-

Lower Operating Costs

Cold Jet dry ice blasters are engineered for efficiency, consuming less dry ice and less compressed air than other machines on the market. These savings compound across projects, reducing your operating costs while maintaining superior cleaning performance.

-

Unmatched Support and Training

Our regional service technicians are always accessible. Cold Jet provides expert maintenance services and comprehensive training to ensure your team’s success from day one.

OUR CUSTOMERS & WHAT THEY SAY ABOUT US

Restoration professionals around the world rely on Cold Jet

With a global installed base of 24,000+ machines, Cold Jet delivers real value to restoration and remediation contractors of all sizes.

Frequently Asked Questions

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.