Dry ice blasting is good because it can be used around electricity, there’s no waste and it’s green. Municipalities are into green or environmentally friendly approaches; that’s another advantage. Dry ice blasting is a good match to reach every part of the length of the track. Because no water is involved, it can be used around electrical connections.

Dry ice blasting equipment for Public Transportation

Reduce service disruptions and extend asset life

For public transportation systems, clean equipment is crucial for reliable and high performing operations.

Dry ice blasting provides a non-conductive, environmentally sustainable cleaning process that is residue free and does not create secondary waste.

With unparalleled versatility, it is both delicate enough to clean sensitive electrical equipment without damage and aggressive enough to remove thick grease and burnt carbon from hard metal surfaces.

Asset Maintenance

Reduce cleaning time by eliminating water and secondary waste

Benefits

Dry ice blasting cleans equipment more quickly by replacing time consuming, manual cleaning methods with chemicals and water, which must be collected and disposed of.

- Reduce risk of unplanned service stoppages and costly repairs

- Minimize service disruptions

- Reduce cleaning time and resulting downtime

- Eliminate manual cleaning with harmful chemical solvents

- No secondary waste

- Reduce water and sanitation costs

- Clean hot and online

- Eliminate re-lubrication

- Non-abrasive Will not damage equipment

- Environmentally sustainable

Specific use cases:

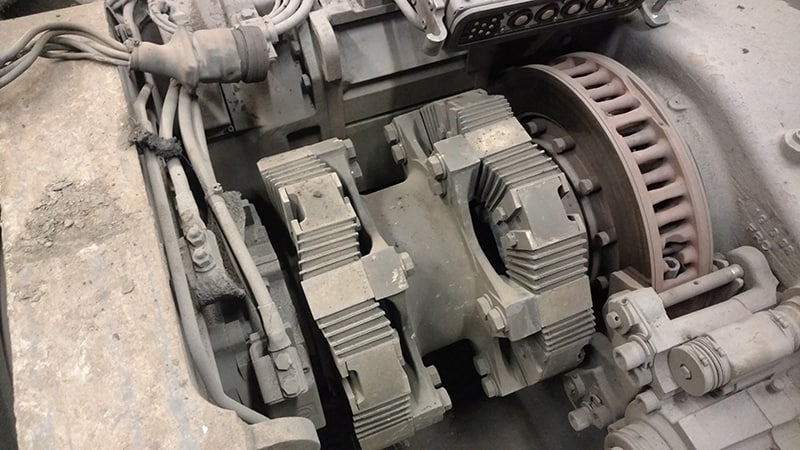

- Traction motors

- Brake controllers

- Cam controller boxes

- Switch gears

- Interior refurbishing

- 3rd rail insulators

- Generators

- Diesel and electric motors

- Rails – Low voltage side

- Degreasing

- +More

Benefits of Dry Ice Blasting

Maintain a high performing public transportation system

Dry ice blasting allows public transportation operators to clean operating equipment more effectively, which reduces the risk of system failure and minimizes service disruptions.

- Reduce service disruptions and downtime

- Extend traction motor and cam controller life

- Non-abrasive No damage to delicate equipment

- No secondary waste stream

- Environmentally sustainable

- Reduce failures of controllers and actuators

- Non-corrosive

- Non-conductive

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.