Plastics & Composites

Dry ice blasting provides water-free surface preparation that ensures optimal paint and coating adhesion

Manufacturers face many challenges in achieving consistent, high-quality surface preparation before painting or coating. Adhesion failures frequently stem from inadequate surface cleanliness, contamination, inconsistent preparation, or unknown residues. Preparing plastics for paint poses added complexity due to their low surface energy and common use of mold-release agents, which can act as invisible barriers to bonding.

Dry ice blasting is a water-free surface prep tool and degreasing tool that completely removes mold release agents, particulate, oils, dust, fingerprints, and manufacturing residues from plastic parts before painting or coating applications. The paint surface preparation method is non-abrasive, maintains surface integrity, and does not create an anchor profile. Dry ice blasting is non-aqueous, which eliminates drying time and provides immediate paint-ready surfaces. The surface preparation process activates the surface and delivers superior contaminant removal across substrates.

Contact us today to discover how our dry ice cleaning machines can enhance your surface prep processes for painting and coating applications.

Dry ice blasting provides superior contaminant removal and immediate paint-ready surfaces

Manufacturing and paint shop operations require consistent, high-quality surface preparation and degreasing to prevent coating failures and ensure proper paint bonding. Traditional surface prep methods, such as spray washers, ultrasonic tanks, and solvent wiping, often involve water-based cleaning that requires cumbersome drying processes and harsh chemicals that leave residues. Manual surface prep tools are often inconsistent, which can lead to defects like peeling, flaking, or poor coating uniformity. These conventional approaches slow production cycles, compromise coating quality, and create additional waste streams that increase operational costs.

Dry ice blasting eliminates water and drying time while providing thorough contaminant removal in coating surface preparation and paint surface preparation applications. Dry ice sublimates upon contact, leaving no residual media, chemicals, or moisture that could interfere with coating adhesion. Dry ice cleaning prepares surfaces for immediate painting or coating application, significantly speeding up production cycles.

Dry ice blasting effectively removes all problematic contaminants including mold release agents, lubricants, microscopic dust and particulate, fingerprints and skin oils, and production residues. The surface preparation and degreasing process creates a clean surface that allows paints and coatings to directly bond with the substrate, preventing issues like fish eyes, blistering, and premature coating failure. The dry ice blasting surface prep tool provides greater longevity for coating bond strength compared to other paint surface preparation methods.

Dry ice blasting is a dry surface preparation method that provides immediate paint-ready surfaces. This eliminates the need for costly drying ovens and water reclamation systems. Parts can move from cleaning to the paint booth with ease, significantly reducing cycle times and increasing production.

Dry ice sublimates into gas upon impact. No cleaning media, chemicals, or moisture remains on parts. This eliminates post-cleaning processes, reduces disposal costs, and ensures no interference with coating adhesion.

Dry ice blasting is a non-abrasive surface preparation method that does not leave an anchor profile. It thoroughly removes surface contaminants and preserves the integrity of plastic parts and delicate surfaces. The coating surface preparation and paint surface preparation method maintains original surface texture and geometry, ensuring consistent coating thickness.

Dry ice blast cleaning for plastic paint preparation, coating surface preparation, and degreasing helps manufacturers achieve superior coating performance across multiple industries. Dry Ice blasting is capable of performing to SSPC-SP-1 (Solvent Cleaning) and SSPC-SP-7/NACE 4 (Brush-Off Blast Cleaning) in coating preparation and prepping plastic for painting.

Dry ice blasting is a water-free and non-abrasive solution that completely removes contaminants from plastic parts.

By eliminating water, dry ice blasting allows for immediate painting or coating of plastic parts, without drying time. This significantly speeds up the production process. Dry ice blasting surface prep and degreasing removes the need for costly drying ovens and water reclamation systems in paint surface preparation and coating surface preparation applications.

Dry ice blasters effectively remove problematic contaminants from the production process, such as mold release agents, oils, dust, and other manufacturing residues. No water, chemicals, or secondary media will be left on the part from the cleaning process. Dry ice creates a truly clean and activated surface on plastic parts, ensuring that paints and coatings bond properly without issues like peeling or bubbling.

Dry ice cleaning is non-abrasive, ensuring delicate plastic surfaces are cleaned without etching, scratching, or altering the part’s geometry or finish. This is crucial for preserving the aesthetic quality and dimensional integrity of plastic components when prepping plastic for painting.

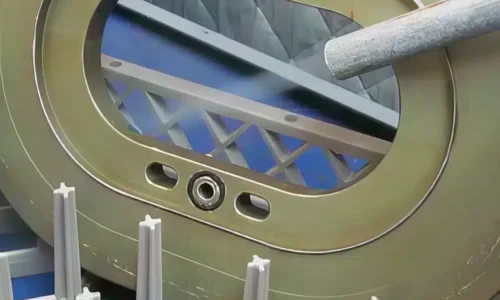

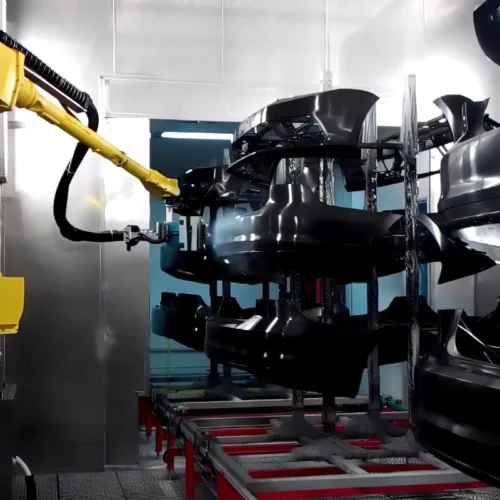

Cold Jet dry ice cleaning machines are designed for easy integration into existing automated production lines. The surface prep process is effective at cleaning plastic parts in automated paint lines, coating lines, and production line systems in a variety of industries:

A complete dry ice surface preparation system requires the following essential equipment:

Surface preparation with dry ice blasting requires a reliable and easy to use dry ice blasting system. Cold Jet provides a diverse range of systems, including models with features like our patented Particle Control System (PCS®). The PCS enables you to fine-tune blasting parameters to precisely fit your application. All dry ice blasters come complete with a blast and air hose, an applicator, and a nozzle that is best suited for your surface prep application.

Compressed air can be supplied from your facility’s existing filtered air system. Cold Jet dry ice blasters typically need 100 cfm (2.8 m³/min) at 80 psi (5.5 bar) to operate effectively.

We can help you identify a dry ice supplier and recommend the amount you should order based on your needs. Once identified, you can establish a delivery schedule that aligns with your production schedules.

Comprehensive training is provided on safe and effective operation, including proper techniques for plastic paint preparation and safety protocols. Cold Jet offers a training course that teaches your team how to use the machine safely and correctly.

Staff should have appropriate safety gear while using the dry ice surface prep tool, including gloves, hearing protection, and eye protection.

Surface prep processes using dry ice blasting are commonly automated — especially for preparing plastic for paint. Fully automated dry ice blasting systems combine a dry ice maker, dry ice blaster, and robotic arm in one system for consistent, repeatable results.

Cold Jet offers a comprehensive range of dry ice blasting machines for surface preparation applications. Our user-friendly machines are ideal for preparing surfaces before painting and coating operations. Cold Jet dry ice blasting machines are capable of achieving a surface condition that meets the SSPC-SP 1 Solvent Cleaning standards.

The Aero2 PCS ULTRA is a versatile surface prep tool for a variety of surface preparation applications, from extremely gentle cleaning with MicroParticle dry ice on delicate plastic surfaces to aggressive cleaning of larger components with 3 mm dry ice granules. The PCS ULTRA can be integrated into your production line for automated surface prep.

Aero2 PCS® ULTRAThe i3 MicroClean 2 is the next generation of precision surface preparation. It offers better efficiency and intuitive controls in a lightweight and compact system. Easily control cleaning aggression to lock in the ideal parameters for coating surface preparation and preparing plastic for paint. The MicroClean 2 can also be integrated into paint lines or production lines for automated surface preparation.

i3 MicroClean® 2The i3 MicroClean is an efficient, lightweight machine that is effective for surface prep applications across multiple industries. Integrate it into your process as an automated surface prep solution.

i3 MicroClean®

If you’re upgrading your surface prep process before painting or coating, investing in a Cold Jet dry ice blaster enhances your operation’s efficiency while ensuring optimal coating adhesion. When evaluating this capital investment, consider both the return on investment (ROI) and operational benefits. Cold Jet machines deliver faster ROI and greater value.

Decades of field-tested performance in various industries demonstrate Cold Jet’s ability to provide superior results for prepping plastic for painting and coating preparation.

Cold Jet has more than 24,000 installed systems globally, including in paint shops, coating lines, and automated production lines from small specialty manufacturers to leading manufacturing facilities.

Cold Jet equipment is engineered for demanding industrial environments, delivering years of dependable operation that keeps your surface preparation process running smoothly with minimal downtime. Cold Jet dry ice blasters have significantly longer machine life than competitors, ensuring consistent performance over time.

Our field service specialists work closely with your team to provide hands-on training and ensure peak system performance of your dry ice surface preparation equipment. Should any unforeseen issues arise, rest assured they will be addressed swiftly and effectively to minimize any impact on your operations.

Our dry ice blasters use significantly less dry ice, compressed air, and electricity than competitor machines. This helps you control operational costs in your surface preparation and coating processes.

Our wide range of accessories, including applicators, blast hoses, and application-specific nozzles help you ensure your dry ice surface preparation equipment is perfectly configured for your unique surface preparation and coating requirements.

With a global install base of 24,000+ that consists of companies large and small, Cold Jet delivers valuable dry ice blasting surface preparation equipment.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.