Plastics & Composites

Clean Plastic Molds and Rubber Molds in a Fraction of the Time with Dry Ice Cleaning

Maintaining clean mold cavities and vents on industrial molds is a major concern for plastic, rubber, and silicone part manufacturers. Cleaning resin, off-gasses, cured material, or mold release agents from mold cavities and vents prevents numerous molding problems, such as mold fouling, clogged vents, short shots, plate-out, splay, burns, flash, and contamination. Industrial mold cleaning is often delayed because traditional methods cause extended downtime and often involve the use of chemicals or mechanical means that are harmful to employees, abrasive to the tooling, and can wear away critical mold tolerances.

Dry ice blasting for plastic mold cleaning and rubber mold cleaning is non-abrasive, does not create secondary waste, and can be done while the mold is still hot and online. The industrial mold dry ice cleaning process is effective for all types of industrial mold cleaning, including plastic injection mold cleaning and rubber mold cleaning. The mold cleaning equipment helps molders improve OEE scores, reduce annual costs, and meet stringent industry demands. Dry ice cleaning machines enable molders to clean contaminants from cavities, vents, and hard-to-reach areas faster, more thoroughly, and more economically than traditional industrial mold cleaners.

Discover how our dry ice cleaning machines can transform your industrial mold cleaning process.

Dry ice blasting cleans molds while still hot and online, enabling increased production cycles, improved part quality, and reduced scrap rates.

Traditional plastic and rubber mold cleaning methods involve tedious and ineffective manual processes using chemicals and hand tools. These methods are abrasive and degrade mold surface finishes and mold integrity, impacting part quality and reducing mold lifespan. Processes like laser cleaning risk stripping the mold of its protective coating and are not effective on highly polished or reflective surfaces. Additionally, these methods require that the mold be removed from production (cool down, disassembly, and reassembly), causing significant downtime and labor costs.

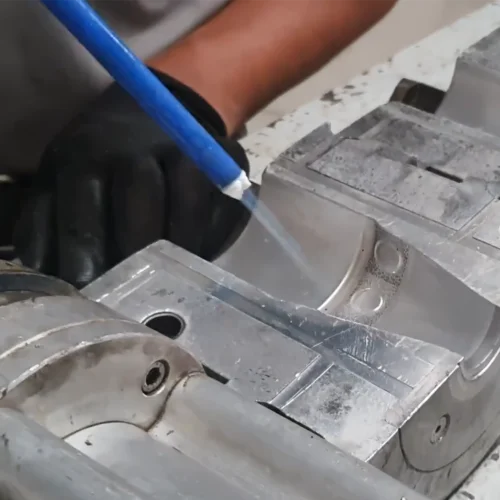

Dry ice cleaning is non-abrasive and effectively removes contaminants without damaging delicate mold surfaces. Molds can be cleaned at operating temperature and in-situ. This eliminates the need for cool down and disassembly, which allows molds to be cleaned in a fraction of the time – drastically reducing production downtime.

The mold cleaning equipment removes resin off-gasses, cured material, and mold release agents from all areas of the mold, including cavities, crevices, vents, and hard to reach areas. Dry ice blasting cleaning reduces mold cleaning times by up to 75% and helps plastic molders meet stringent productivity demands. It helps molders clean faster, better, and more economically, increasing production capacity and improving product quality.

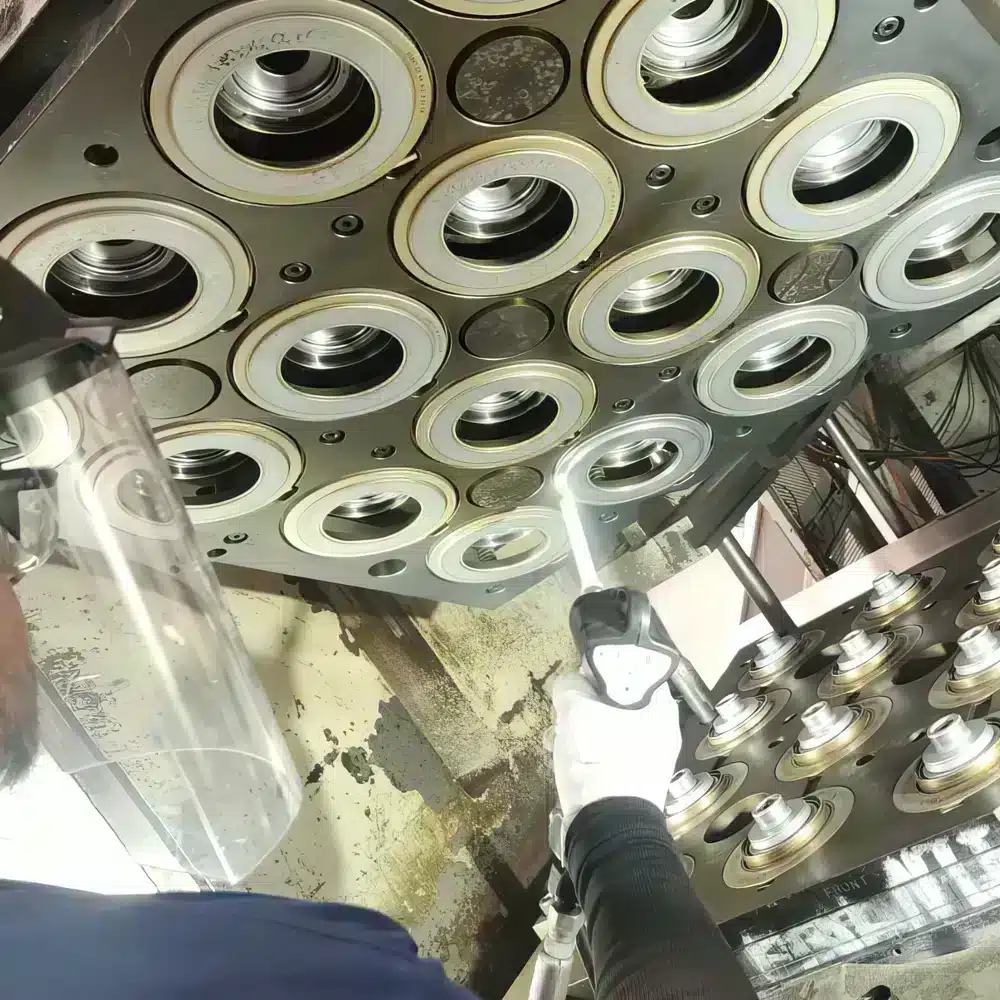

Dry ice blasting equipment cleans industrial molds at operating temperature while they are still online without causing thermal stress. Cleaning in-situ eliminates downtime associated with the cooldown, disassembly, and reassembly processes. Injection mold cleaning can be done while the mold is still in-press with dry ice cleaning. Molds can be cleaned more frequently, which significantly increases production cycles and decreases rejection rates. Dry ice blasting equipment for plastic molds is also a more efficient process if cleaning must be done offline.

Dry ice cleaning is non-abrasive and will not cause mold wear or affect mold finishes or critical mold tolerances. This ensures consistent and repeatable results, higher quality parts, and less scrap. The plastic mold cleaning equipment is safe and effective on Class A through D surfaces. Dry ice cleaning significantly reduces high tooling replacement costs and prolongs the lifespan of valuable molds.

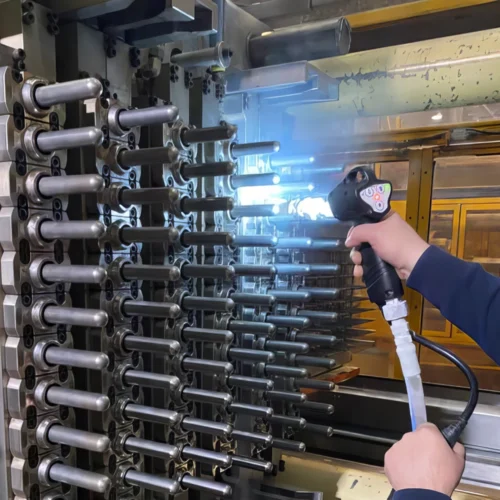

Dry ice blasting excels at cleaning the intricate details and tight spaces found in plastic and rubber molds. Dry ice easily cleans complex mold geometries and hard-to-access areas that other methods often miss.

Dry ice blasting cleaning offers a distinct advantage because it produces no secondary waste. As dry ice sublimates into a gas upon impact, there’s no need for water, harsh chemicals, or other cleaning solutions. This means no moisture, chemicals, or secondary media residue are left on the mold or finished part, preventing cross-contamination and scrapped parts.

Dry ice cleaning helps plastics and rubber manufacturers achieve superior part quality and meet contract specifications. Because the process cleans industrial molds in-place and in a fraction of the time, they can be cleaned more frequently. This leads to consistently high-quality parts, significantly reducing scrap rates and rejected products.

Dry ice cleaning is safe and effective for Class A-D surface molds. The industrial mold cleaning process is being used to clean all types of plastic and rubber molding equipment.

Dry ice blasting machines help plastics and rubber manufacturers reduce scrap and downtime, improve product quality, prolong the life of their equipment, and increase profitability.

Traditional plastic injection mold cleaning and injection mold maintenance products require significant downtime and can be abrasive to the mold. Dry ice blasting for plastic injection mold cleaning cleans molds while still hot and in the press, immediately after a cycle, eliminating the need to wait for molds to cool and be disassembled. By cleaning plastic injection molds consistently, they remain clean and calibrated, which leads molders to experience increased production and efficiency. Dry ice cleaning machines are an ideal injection mold cleaner.

A major problem faced by rubber molders is mold fouling. Buildup of cured material and sacrificial mold release agents causes sticking molds, blemishes, and unwanted flash on final parts, making them unusable and requiring line shutdowns for cleaning. Traditional cleaning methods such as manual scraping, glass bead blasting, or ultrasonic cleaning can be time consuming, ineffective, damaging to molds, and result in high labor and material costs. Dry ice cleaning offers an in-place, online, quick, and effective way to clean at operating temperatures without causing damage to expensive molds.

Dry ice cleaning machines help packaging molders meet stringent productivity demands. They help molders clean faster, better, and more economically, increasing production capacity and improving product quality. Dry ice cleaning allows molds, lock rings, cores, and gate inserts to be cleaned without the disassembly of the stripper plate and while the mold is still in the press.

Industrial mold dry ice cleaning allows aluminum molds, even with beryllium inserts, to be cleaned hot and in-place. The non-abrasive method requires no chemicals and produces no secondary waste. Cold Jet’s specially designed nozzles and applicators allow for cleaning in hard-to-reach spaces to ensure a complete clean every time. A quicker clean means more production time, and the thorough clean allows for consistent quality products with less scrap.

Molders are very familiar with the requirements of precision, high-tolerance, and micro-molding parts and the difficulties that come with them. Keeping small orifices and complex geometries of micro-cavity production molds clean is a critical concern when manufacturing high tolerance plastic parts. Dry ice cleaning easily and efficiently cleans technical production molds.

Because silicones flash very easily, molds for these high-performance thermoset elastomers are manufactured to critical tolerances, often +/- .0002 inches. During cleaning, protecting the critical dimensions on parting lines, sealing surfaces, and mold finish is vital. Industrial mold dry ice cleaning makes it easy to keep the vents open in order to evacuate the air out of the mold prior to injection – this helps to produce high quality molded parts. With dry ice cleaning, you can clean molds in the machine at processing temperature without causing mold wear.

Cold Jet offers dry ice cleaning equipment for plastic molds, rubber mold dry ice cleaning equipment, and injection mold cleaners for a variety of industries.

An industrial mold dry ice cleaning configuration at your site relies on several key parts:

A successful industrial mold cleaning process starts with an easy to use and mobile dry ice cleaning machine. Cold Jet offers a complete range of dry ice blast cleaning machines, featuring advanced models with IoT connectivity and our patented Particle Control System (PCS®). This innovative technology gives you the power to precisely adjust cleaning parameters and dry ice particle size, allowing for very delicate to more aggressive cleaning. Each blaster arrives ready with blast and air hoses, an applicator, and a nozzle for your specific application.

Most molding facilities have existing filtered air systems that can supply the required compressed air. Cold Jet dry ice blasters typically need 100 cfm (2.8 m³/min) at 80 psi (5.5 bar) to operate effectively.

A reliable supply of dry ice is needed to ensure you have dry ice when you need it. Average consumption is approximately 88 lbs. per hour. We can help you identify a dry ice supplier and recommend the amount you should order based on your needs. Once identified, establish a delivery schedule that aligns with your maintenance and production schedules.

To ensure your team can effectively and safely use your dry ice cleaning equipment for plastic molds, proper training is essential. Cold Jet provides a comprehensive training course that equips operators with the necessary techniques and safety guidelines for optimal cleaning practices.

Always ensure your cleaning team wears the correct safety gear, including gloves, hearing protection, and eye protection when operating your plastic mold cleaner or injection mold cleaner.

Cold Jet provides a full range of dry ice blasters specifically for plastic mold cleaning and rubber mold cleaning. Our systems are user-friendly, built to last, and are easily portable, making them perfect for any molding operation.

The Aero2 PCS ULTRA is a highly versatile machine for all types of plastic molds and rubber molds. The mobile dry ice blaster handles everything from gentle cleaning with MicroParticle dry ice to aggressive cleaning of larger molds using 3mm dry ice. The machine is an ideal industrial mold cleaner and injection mold cleaner.

Aero2 PCS® ULTRAThe i3 MicroClean 2 features intuitive controls in a lightweight, compact design. Users can easily transport the dry ice blaster right up to the molding machine. You can easily adjust cleaning parameters to lock in the ideal settings for your specific application. The mold cleaning equipment is ideal for plastic mold cleaning, cleaning plastic injection molds, and plastic mold maintenance.

i3 MicroClean® 2The i3 MicroClean is an efficient, lightweight, and time-tested dry ice cleaning machine that is ideal for any type of plastic mold cleaning or rubber mold cleaning application, including plastic injection mold cleaning.

i3 MicroClean®

Cold Jet offers a wide range of plastic mold dry ice cleaning equipment, rubber mold dry ice cleaning equipment, and injection mold cleaners. When incorporating dry ice blasting into your plastic mold cleaning and rubber mold cleaning processes, you need a durable and reliable machine that you can count on when you need it. Cold Jet machines deliver faster ROI and greater value than competitors.

With decades of experience in the plastics and rubber sectors, Cold Jet has developed an unparalleled understanding of the critical cleaning challenges and operational demands that plastics molders and rubber molders experience.

With over 24,000 dry ice cleaning machines installed worldwide, including at leading plastics and rubber manufacturers, Cold Jet is the trusted solution for industrial mold dry ice cleaning.

Our machines are engineered to thrive in high-production environments. Cold Jet dry ice blasters offer unmatched reliability and a significantly longer lifespan than competitor models.

Cold Jet dry ice cleaning equipment for plastic molds is designed for maximum efficiency, using significantly less dry ice, compressed air, and electricity than competitor machines. This directly reduces your daily operating costs without compromising on the highest standards of cleaning quality or safety.

Our regional technicians are readily available and bring a deep understanding of the unique needs of molders. We offer both expert maintenance services and comprehensive equipment training to ensure your team’s success.

Cold Jet offers a wide array of accessories, including various applicators, blast hoses, and application-specific nozzles, so you can perfectly configure your setup for your unique operational needs. We will help you find the perfect nozzle for your specific mold.

With a global install base of 24,000+ that consists of companies large and small – Cold Jet delivers valuable dry ice cleaning equipment for plastic molds and rubber molds.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.