Plastics & Composites

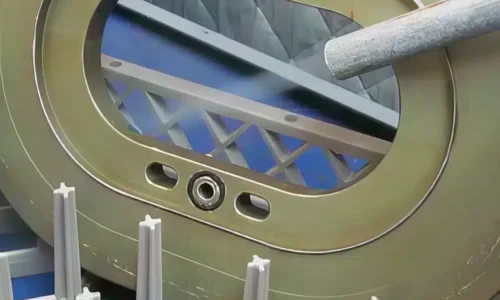

Safely and Quickly Clean Composite Molds Online While Preserving Critical Tool Surfaces

Manufacturers producing high-quality composite parts for aerospace, defense, automotive, and other commercial sectors require the highest standards of part consistency and precision. Effectively cleaning tooling and composite molds of release agents, resins, and production residues is critical to consistently producing high-quality parts. Maintaining precise mold surfaces without damage is essential for high quality final products, tool longevity, and production efficiency.

Dry ice blasting is a non-abrasive composite tool cleaning solution that will not alter dimensions, mold tolerances, or surface finish of composite molds – ensuring the integrity of finished composite parts and prolonging the tool service life. Composite molds can be cleaned in-line at operating temperatures, eliminating the need for costly cooldown and reheating cycles, and significantly reducing downtime.

Contact us today to discover how our dry ice cleaning machines can enhance your composite tooling maintenance and extend the operational life of your expensive composite tooling.

Dry ice blasting enables composite molds to be consistently and reliably cleaned while maintaining precision tolerances

Traditional cleaning methods for composite tooling are often slow, labor intensive, and reduce the productive life of valuable tooling. Manual processes using wire brushes, abrasive pads, and harsh chemicals can wear away critical tolerances and damage mold surfaces. Chemical cleaning and abrasive media blasting present safety hazards and disposal challenges.

Non-abrasive dry ice cleaning preserves mold surfaces and tool integrity. It is a more efficient process for removing contaminants from composite molds without compromising precision features. The cleaning process improves part consistency and quality while reducing scrap rates and tool replacement costs.

Dry ice blasting preserves critical dimensional tolerances, shutoffs, and parting lines that are often worn away by traditional cleaning methods. The process does not etch, profile, or change dimensions of tool surfaces, maintaining precision geometries essential for quality part production. Complex geometries, tight corners, and intricate details are thoroughly cleaned without wear or damage. Dry ice cleaning significantly reduces tooling replacement costs and prolongs the lifespan of valuable molds.

Dry ice blasters clean composite molds while they remain hot and online. This eliminates downtime associated with cooldown, disassembly, and reassembly processes. It eliminates time-consuming manual cleaning methods and provides a more thorough clean. Molds can also be cleaned more frequently, which significantly decreases rejection rates and increases production output.

Dry ice cleaning can remove a variety of contaminants from many different types of tooling substrates. The process effectively removes resin, release agents (sacrificial, semi-permanent, permanent), base coats, epoxy, Teflon tape, tacky tape, silicones, production oils, polymer residues, phenolic materials, carbon and graphite fibers, Kevlar, oxides, and other production residues.

Dry ice sublimates upon contact, leaving no blast media, chemical residue, or secondary waste to clean up. Cold Jet dry ice blasting ensures no foreign object debris (FOD). This eliminates additional cleaning steps, reduces contamination risks, and ensures optimal surface conditions for subsequent production cycles.

Studies confirm that dry ice cleaning causes no thermal stress to tooling substrates. Temperature changes occur only at the surface level, with no penetration that could cause dimensional changes or cracking. Molds operating at elevated temperatures actually clean more effectively due to enhanced thermal shock effects.

Dry ice cleaning uses recycled CO2 and doesn’t contribute to greenhouse gas emissions. It eliminates the need for harmful VOCs and hazardous cleaning chemicals, creating a safer work environment.

Dry ice blast cleaning is effective across all composite manufacturing processes and can remove various contaminants while preserving tool integrity.

Dry ice blasting provides precise, controlled cleaning for intricate mold geometries and tight tolerance applications.

Dry ice blasting cleans composite tooling for aircraft components, engine parts, structural elements, and interior panels. The composite tool cleaning process removes release agents, prepreg residues, and production contaminants from critical aerospace molds while maintaining strict quality standards and surface specifications. Dry ice cleaning prevents foreign object debris.

Dry ice cleaning maintains composite molds for body panels, interior components, under-hood parts, and structural reinforcements. It cleans SMC and BMC compression molds, RTM tooling, and pultrusion dies efficiently while preserving tool precision and extending service life.

Maintain composite tooling for wind turbine blades, nacelles, and structural components with dry ice blasting. Clean blade molds and production tooling efficiently while preserving the precision required for aerodynamic performance and structural integrity.

Cold Jet offers dry ice cleaning equipment for composite molds, tooling maintenance, and precision cleaning solutions across multiple manufacturing environments.

When implementing dry ice cleaning in your facility, the following components are essential for an effective setup:

A successful composite tool cleaning program begins with selecting the right dry ice blasting equipment for your specific needs. Cold Jet’s comprehensive machine lineup includes advanced models featuring our patented Particle Control System (PCS®), which allows precise adjustment of cleaning intensity to match your exact composite tooling requirements.

Dry ice blasting equipment integrates seamlessly with your current compressed air supply. Cold Jet dry ice blasters typically need 100 cfm (2.8 m³/min) at 80 psi (5.5 bar) to operate effectively.

We provide guidance in selecting reliable dry ice suppliers and determining the appropriate amount you will need to order based on your needs. Once identified, you can establish a delivery schedule that aligns with your production and preventative maintenance plans.

Comprehensive training is provided on safe and effective operation, including proper techniques and safety protocols. Cold Jet offers a training course that teaches your team how to use the machine safely and correctly.

Composite tool cleaning staff should wear proper safety gear, including gloves, hearing protection, and eye protection.

Cold Jet offers a comprehensive range of dry ice blasting machines for composite parts manufacturing environments. Our user-friendly machines are ideal for composite tool cleaning and maintenance applications.

The Aero2 PCS ULTRA is a versatile machine for a variety of composite cleaning applications, from extremely gentle cleaning with MicroParticle dry ice to aggressive removal of heavy contamination with 3mm dry ice pellets. The Particle Control System provides precise parameter control for optimal results.

Aero2 PCS® ULTRAThe i3 MicroClean 2 is the next generation of precision cleaning. It offers improved efficiency and intuitive controls in a lightweight and compact system. Easily control cleaning parameters to optimize performance for your specific composite tooling applications.

i3 MicroClean® 2The i3 MicroClean is an efficient, lightweight machine that is highly effective for composite mold cleaning and maintenance applications. Its compact design makes it ideal for integration into existing production environments.

i3 MicroClean®

If you are upgrading your composite tool maintenance process, investing in a Cold Jet dry ice blaster enhances your operation’s efficiency, extends tool service life, and improves part quality. When evaluating this capital investment, consider both the return on investment (ROI) and operational benefits. Cold Jet machines deliver faster ROI and greater value.

Decades of field-tested performance in various industries demonstrate Cold Jet’s ability to provide superior results for cleaning composite molds and tooling.

With more than 24,000 machines installed globally, we’ve established ourselves as the trusted solution for tooling maintenance in composite parts manufacturing.

Cold Jet equipment is engineered for demanding industrial environments, delivering years of dependable operation that keeps your composite tool cleaning process running smoothly with minimal downtime. Cold Jet dry ice blasters have significantly longer machine life than competitors, ensuring consistent performance over time.

Our regional technicians understand the unique requirements of composite manufacturing environments and are always accessible. We deliver both maintenance services and comprehensive equipment operation training. If unexpected problems occur, our team responds quickly to reduce operational disruption.

Cold Jet machines consume substantially less dry ice, compressed air, and power compared to competing equipment, lowering your daily operating costs without compromising cleaning performance or safety standards.

Our comprehensive accessory lineup, featuring specialized applicators, blast hoses, and specialized nozzles, enables you to tailor performance to your unique composite tool cleaning needs.

With a global install base of 24,000+ machines serving companies large and small, Cold Jet delivers real value to composite parts manufacturers worldwide.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.