We were impressed with its ability to clean the contaminants from the printer safely, which also minimized our need to use chemicals.

Dry Ice Blasting for Printing Equipment

Efficiently clean printing machinery in-place without chemicals

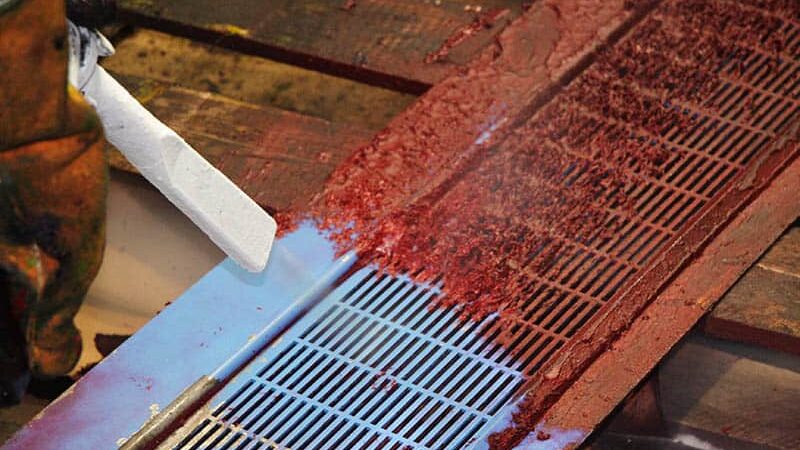

When you clean printing presses with dry ice blasting, cleaning is completed with little to no disassembly or downtime. The process easily and accurately cleans burnished ink, heavy grease and caked on paper dust without chemicals or damage to sensitive and expensive components.

Printing Equipment Cleaning

Clean more efficiently and reduce downtime and scrap rates

Benefits

Dry ice blasting machines quickly and easily removes buildup from printing machinery components.

- Non-abrasive Will not damage equipment

- Reduce scrap rates

- No secondary waste

- Reduce cleaning time and resulting downtime

- Reduce labor costs

- Clean online

- Eliminate manual cleaning

- Environmentally sustainable

- Employee safe

Specific use cases:

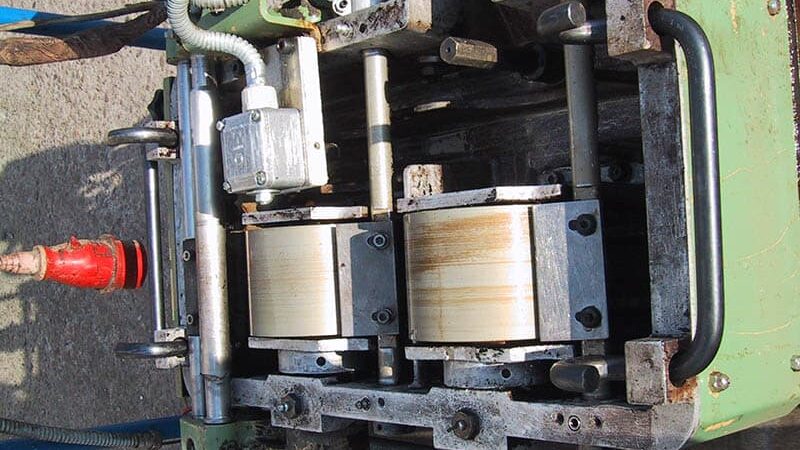

- Drums

- Feeder units

- Delivery units

- Flexography

- Gear and deck guides

- Grippers

- Rollers

- Gravure presses

- Ink trays

- Letterpresses

- Side walls

- Vent slots

- Electronic components

- +More

Benefits of Dry Ice Blasting

Always ensure that your printing operation produces top quality and operates at peak efficiency

Dry ice cleaning is a more effective cleaning solution that provides the ability to clean in-place, without chemicals and without damage, which results in higher performing machinery, increased quality, reduced scrap rates and prolonged equipment life.

- Non-abrasive Will not damage equipment

- Reduce scrap rates

- No secondary waste stream

- Reduce cleaning time and resulting downtime

- Reduce labor costs

- Clean hot and online Minimal to no disassembly required

- Eliminate manual cleaning with harmful chemical solvents

- Environmentally sustainable

- Reduce risk of unplanned production stoppages and costly repairs

- Operationally safe Eliminate manual cleaning and exposure to unsafe conditions

Case Studies

Proven technology produces definable results

Our solutions are driving real results in our customers’ organizations.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.