Dry Ice Blasting Applications:

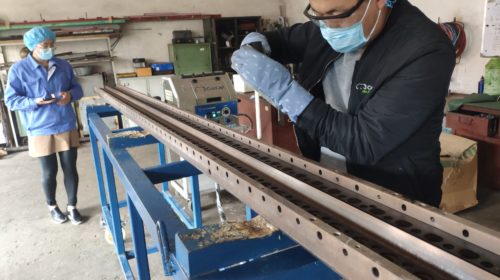

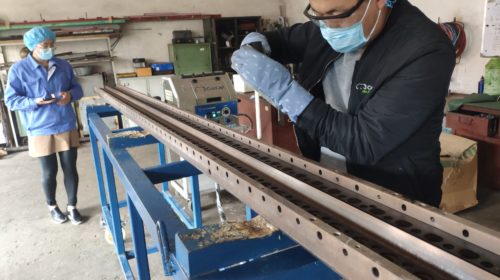

Dry Ice Blasting for Non-Woven Die Cleaning

A safer and more effective method for removing polymer buildup from production dies. Easily remove polymer buildup from the holes in the spinnerets or dies.

Manufacturers of polymer nonwoven products are increasing production rates with dry ice blasting. Regardless of the manufacturing method, spunbond, melt-blown, wet-laid, or needle-punch, cleaning is an integral part of maintaining and improving product quality and productivity.

Traditional cleaning methods of a melt-blown die can take many hours and multiple shifts. Cleaning with Cold Jet’s dry ice MicroParticles is measured in only minutes depending on the size of the die. This significantly reduces production downtime.

SPECIFIC USE CASES

Dry ice blasting effectively removes various polymers (PP, PET, TPU, PA, PE, PC, PS, etc.) from dies utilized to manufacture a variety of nonwoven products

- Facemask media

- Medical wipes and fabrics

- Automotive acoustical panels

- Baby and child hygiene

- Sanitary products

- Filtration media

- Oil absorbents

- Battery separators

- Barrier fabrics

- Apparel

- Coffee filters

- Dual texture wipes

- +More

RELATED INDUSTRIES

Benefits of Dry Ice Blasting

The dry ice blasting process brings a variety of advantages over traditional cleaning methods.

The process is non-abrasive and extends the asset life of the die. With dry ice, there is no longer a need to manually drill out die holes or scrape off excess polymer. Dry ice blasting is a dry process and does not require water or ultrasonic tank cleaning and does not produce secondary waste. It is also environmentally sustainable and eliminates the use of chemicals.

- Improve productivity of production lines

- Improve product quality and decrease scrap rates

- Reduce production downtime

- Prolong equipment lifeSignificantly reduce replacement costs

- Eliminate harmful and caustic chemicals

- No secondary waste streams

- Environmentally sustainable

Case Studies

Dry ice blasting is improving our customers’ organizations

-

Kunststoffen & composieten

Kunststoffen & composieten

WIJ ZIJN ER OM U TE HELPEN.

Geïnteresseerd maar weet u niet waar te beginnen?

Neem vandaag nog contact met ons op voor meer informatie over onze droogijsstraalmachines en om te ontdekken hoe deze aan uw specifieke behoeften kunnen voldoen.