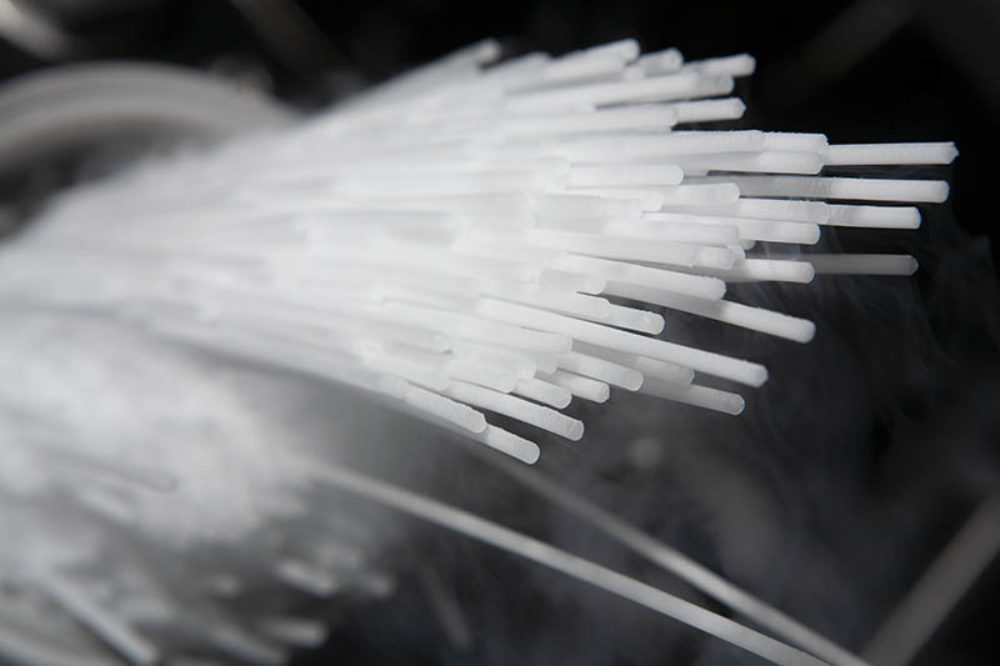

Dry Ice Production Applications

Dry Ice Systems for Food Processors

Maintain critical temperatures in food processing with dry ice

Dry ice is used in many types of food processing facilities – including bakeries – to control temperature, impede bacteria growth and reduce spoilage. Dry ice is a food grade media and is FDA, USDA and EPA approved for use around food.

Cold Jet dry ice machines use 70% less Liquid CO2 than snow horns.

SPECIFIC USE CASES

Dry ice is used in many types of food processing applications

- Meat processing

- Commercial bakeries

- Winemaking (Cryomaceration)

RELATED INDUSTRIES:

Benefits of Dry Ice Production

Gain greater control of your food processing operations

Dry ice is used by meat processors, commercial bakeries and wineries to maintain critical temperatures in order to reduce spoilage during production, inhibit bacteria growth, slow yeast growth and delay fermentation. Food processors that utilize large quantities of dry ice on a daily basis significantly benefit from onsite dry ice production.

- FDA, USDA and EPA approved for use around food

- Cold Jet machines use 70% less liquid CO2 than snow horns

- Colorless, tasteless, odorless and non-toxic

- Reduce spoilage and inhibit bacteria growth

- Does not add residue or water into food products

- Cut costs and improve operational efficiency

- 3x the refrigeration power of water ice

- Greater flexibility to meet demand

- Eliminate dry ice waste

- Eliminate risk of over or under ordering

- Eliminate delivery and storage costs

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.