Dry Ice Blasting Solutions

Providing a more effective and sustainable solution to environmental cleaning, surface preparation and parts finishing applications, without the adverse effects.

Our Technology

Cold Jet is an OEM of dry ice blasting solutions that offer a more effective and sustainable alternative for general cleaning than other methods such as abrasive, soda, and sandblasting. Dry ice blasting, also called dry ice cleaning, is an environmentally sustainable cleaning and surface preparation technique. Dry ice blast cleaning machines use recycled solid carbon dioxide (CO2) pellets or MicroParticles, which are blasted at supersonic speeds and sublimate on impact, lifting dirt and contaminants off the underlying substrate.

Dry ice cleaning is non-abrasive, non-conductive, non-toxic, and non-flammable, giving several advantages over other cleaning methods. CO2 blasting is also chemical free, water free, and does not create secondary waste streams. Our dry ice blasting equipment features unparalleled technology that can be used in a variety of industries and applications.

Benefits of Dry Ice Blasting

- Reduce downtime Significantly quicker process leads to increased production time.

- Increase efficiency Clean equipment online, while eliminating need for cooldown and disassembly.

- No secondary waste Dry ice blasting does not produce secondary waste streams, residue or moisture.

- Non-abrasive Dry ice is a soft media that will not harm substrates.

- Improved part quality and reduced scrap Cleaner machinery and tooling results in higher quality products.

- Environmentally sustainable Dry ice is made of recycled CO2 and does not add additional CO2 to the atmosphere. It also significantly reduces water use for sanitation.

- Operator safe Eliminates need for chemicals and repetitive, manual processes.

- Non-toxic and non-conductive Dry ice is a food grade media and is safe for commercial use.

- More efficiently allocate labor The process reduces time, labor and resources needed.

Dry Ice & CO2 Safety

When working with CO2 , precaution must always be taken to ensure that the area is sufficiently ventilated and that proper PPE is worn when dealing with the liquid or solid form of CO2 (dry ice).

How does dry ice blasting compare to other methods?

Dry ice blasting’s unique characteristics make it a more efficient, cost-effective, and environmentally sustainable cleaning solution than other general cleaning methods.

* Upon contact, traditional blasting materials become contaminated when used to clean hazardous substances and objects. These blasting materials are then classified as toxic waste and require appropriate safe disposal.

Why Cold Jet?

Cold Jet is the pioneer and global leader in dry ice blasting technology, holding the original patent for modern dry ice blasting equipment. With unmatched experience, superior technology, and premium support, you receive much more than a state-of-the-art dry ice blasting machine; you receive the most extensive and expansive customer support resources. Learn more about our dry ice blasting equipment and the ROI it can provide here.

Dry Ice Blasting Overview

Cold Jet’s line of dry ice blasting machines can be used in a variety of applications.

A solution for every application, in all industries

All Industries:

Dry Ice Blasting FAQs

Dry Ice Blasting FAQs:

What is dry ice blasting?

Dry ice blasting, also called dry ice cleaning, is an environmentally sustainable cleaning and surface preparation technique. Dry ice blasting uses recycled solid carbon dioxide (CO2) pellets or MicroParticles, which are blasted at supersonic speeds and sublimate on impact, lifting dirt and contaminants off the underlying substrate. Dry ice cleaning is non-abrasive, non-conductive, non-toxic, and non-flammable. It is also chemical free, water free and does not create secondary waste streams.

How do dry ice blasters work?

Dry ice blasters blast carbon dioxide pellets or MicroParticles at supersonic speeds using compressed air. These pellets/particles then sublimate on impact and lift dirt and contaminants off the underlying substrate.

What is dry ice blasting used for?

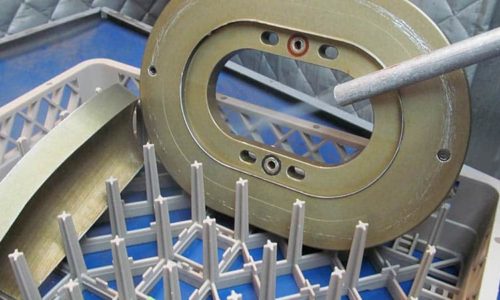

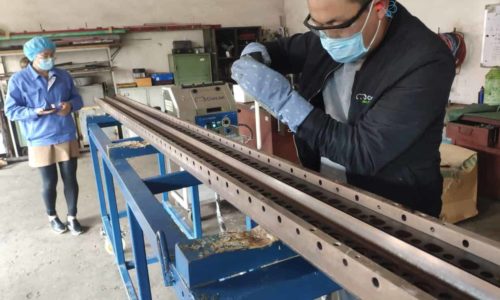

Dry ice blasting is a non-destructive solution for cleaning, surface preparation, and parts finishing. Dry ice blasting does not require water or cleaning chemicals and does not produce secondary waste. Dry ice blasting (cleaning) can be used in industries like aerospace & aviation, automotive, contract cleaning, food & beverage, plastics & composites, restoration, textiles, and more. Common applications within these industries include adhesive removal, coatings & corrosion removal, composite tool cleaning, remediation, parts finishing, and surface preparation. As you can see, dry ice blasting can be used for a wide range of applications.

What are my options for dry ice blasting equipment?

Cold Jet offers our top-of-the-line dry ice blasting equipment both new and used. As the OEM, you can be sure that you’re receiving the best equipment and the customer service/support you deserve. Click here to learn more about our buying options.

Why would I choose dry ice blasting over another cleaning and surface prep method?

Dry ice cleaning offers a non-toxic, environmentally sustainable alternative to traditional cleaning methods that does not create secondary waste in the cleaning process, does not require chemicals, and does not use valuable and expensive water in the cleaning process. It can also reduce time and labor costs when compared to other methods.

Is dry ice blasting dangerous?

Because dry ice blasting involves the use of dry ice, there are certain safety precautions that should be followed to ensure all personnel are safe. Some key precautions include:

- Ensuring proper ventilation

- Limiting exposure

- Identifying and labeling areas where it is possible for CO2 to accumulate

- Wearing and utilizing proper PPE such as gloves, eyewear, and tongs

Dry ice blasting is not inherently dangerous, but there are safety precautions one should always follow. To learn more about CO2 and dry ice safety, click here.

How much does dry ice cleaning cost?

Dry ice blasters range in price from $15k to $45k USD. Speak to a sales associate today for a more tailored quote.

WE ARE HERE TO HELP.

Interested but don’t know where to start?

Contact us today to learn more about our solutions and see how they can meet your unique needs.